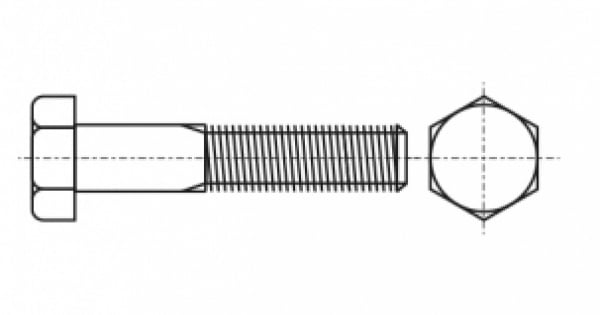

GOST 7796-70 is one of the most common fasteners. It consists of a stud with a partially threaded surface and a hexagonal head. Such bolts are used in all areas of modern production and are among the most popular hardware. The purpose of the bolt is to securely fix elements, parts and structures in cases where the connection is subject to constant vibrations.

Strength class GOST 7796-70

The strength class of a bolt according to GOST 7796-70 is the maximum applied force at which the bolt begins to fracture. Bolts of GOST 7796-70 are manufactured in strength classes from 5.6 to 12.9. From strength class 8.8, a bolt is considered high-strength. High-strength GOST 7796-70 should be purchased only from trusted suppliers. It is made of alloy steel and such bolts are used for critical projects where, in addition to high loads and static loads, GOST 7796-70 bolts are subjected to constant vibration. Such bolts will be especially relevant in bridge construction, instrumentation, and in structures that are located near objects subject to vibration.

Fastening group GOST 7796-70

Hexagonal head bolts are divided into different fastening groups depending on the material of manufacture:

- High-strength fasteners

- Stainless steel fasteners

Materials of manufacture of GOST 7796-70

GOST 7796-70 is produced in the following materials:

- Steel, which can be additionally coated with hot-dip galvanized, ordinary galvanized, yellow galvanized and

- Stainless steel (A2, A4) does not require coating

Where are GOST 7796-70 bolts used?

The scope of application of this fastener is quite wide, since no instrumentation can do without them. Whether it is mechanical engineering or instrumentation. They are also indispensable for assembling parts of special equipment, mechanisms, as well as cars and agricultural machinery. In the construction of buildings, they are often used for frame structures, installation of engineering grids, fire extinguishing systems, and life support. In addition, the scope of application directly depends on the material of manufacture and coating of the product:

- Galvanized steel is a good protection against corrosion if the fasteners are to be used in aggressive environments.

- Stainless steel allows the fasteners to be used at significant temperature drops and in aggressive and humid environments.