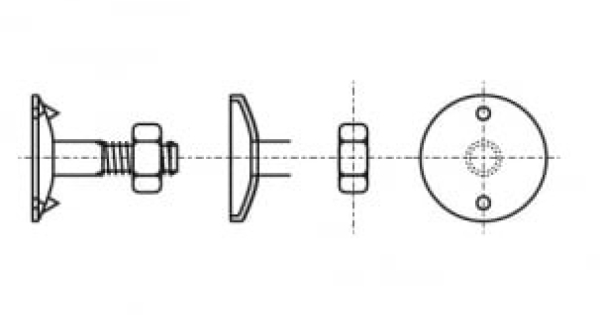

Elevator (bucket) bolt GOST 7811-7074 is a bucket (elevator) fastener with a large countersunk head with two protrusions on the bottom side and a rod with a large pitch full metric thread. Elevator bolts are fasteners that consist of a head and a rod with a metric thread. Elevator bolts are supplied complete with a standard or locking hexagonal nut and a hemispherical elevator washer.

Strength class GOST 7811-7074

The strength class of a bolt according to GOST 7811-7074 is the maximum applied force at which the bolt begins to fracture. GOST 7811-7074 bolts are manufactured in strength classes 3.6, 4.6 and 8.8. From strength class 8.8, the bolt is considered high-strength.

Fastening group of GOST 7811-7074

Depending on the material of manufacture, bolts of GOST 7811-7074 are divided into groups:

- High-strength fasteners - bolts made of steel with strength class 8.8 and above

- Stainless fasteners - bolts are made of stainless steel

Materials for manufacturing bolts of GOST 7811-7074

Bolts of GOST 7811-7074 are made of the following materials:

- Steel of strength classes 3.6, 4.6 and 8.8. Which can be additionally coated with zinc. Zinc protects against corrosion if the fasteners are to be used in aggressive environments.

- Stainless steel. Steel grade A4 allows the fasteners to be used at significant temperature drops and in aggressive and humid environments.

Areas of application for bolts of GOST 7811-7074

The conveyor (elevator) bolt is installed from the side of the conveyor belt through a prepared perforated hole, then a bucket is put on it and fixed with a nut and a plate washer. The elevator bolt should be tightened so that its head is slightly below the surface of the belt (where possible), so that the drive pulley will contact the belt, not the bolts, and will not interfere with the smooth operation of the conveyor.