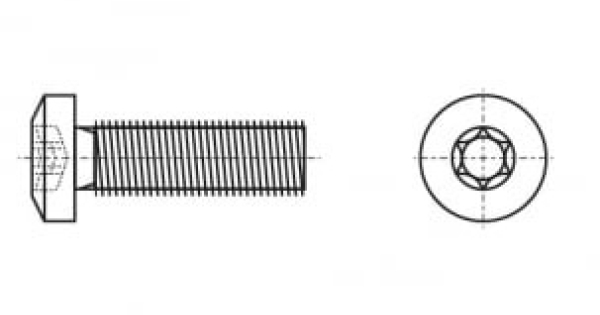

Screw with Semi-Round Head with Torx Drive ISO 14583

The screw with a semi-round head and Torx drive, according to ISO 14583, is designed to offer secure and reliable fastening solutions in various industrial and commercial applications. It is known for its durability and ability to withstand high torque without damaging the drive, making it a popular choice for many industries. This screw is ideal for applications that require high strength and a precise, secure fit.

Technical Specifications of ISO 14583

ISO 14583 defines the technical characteristics of the screw with a semi-round head and Torx drive. This standard specifies dimensions, thread sizes, and material requirements, ensuring that the screw meets the necessary performance standards for reliability and safety.

The dimensions of screws under this standard include the diameter of the thread, the length of the screw, and the dimensions of the semi-round head. The Torx drive feature is designed to provide a better grip than conventional screw heads, reducing the risk of stripping and slippage during installation. The screws are available in various sizes to accommodate different fastening needs.

Strength Class of Screw with Semi-Round Head and Torx Drive ISO 14583

The strength class of a screw is determined by the material it is made from, as well as its intended application. The screws under ISO 14583 typically come in different strength classes, which define the tensile strength and resistance to deformation under load.

- Class 8.8: This class of screw is designed for general use and provides a moderate level of strength suitable for most applications. It can handle moderate stresses and is widely used in construction and manufacturing.

- Class 10.9: These screws are made for applications where higher strength is required. They offer better resistance to deformation under higher loads and are commonly used in automotive and machinery manufacturing.

- Class 12.9: For extreme conditions, screws in this class provide the highest tensile strength, making them ideal for heavy-duty industrial applications where the highest levels of strength and durability are needed.

Fastening Group of ISO 14583

Screws with a semi-round head and Torx drive, as per ISO 14583, belong to the fastener group known as "high-strength fasteners." These screws are typically used in environments that demand reliable and secure fastening, especially where high-torque installation is needed. They are designed to withstand mechanical stresses without failure, providing long-lasting and strong connections in various industrial systems.

These screws are often used in conjunction with other high-strength fasteners, including nuts, bolts, and washers, ensuring the overall stability and integrity of the assembly. The fastener group ISO 14583 is integral in applications requiring secure, tight connections in equipment and machinery.

Materials Used in the Manufacture of Screw with Semi-Round Head and Torx Drive ISO 14583

The material selection for screws under ISO 14583 plays a vital role in their performance and durability. The screws are typically made from high-quality materials that offer strength, corrosion resistance, and the ability to withstand various environmental conditions.

- Carbon Steel: This is the most common material used for manufacturing these screws. Carbon steel provides a good balance of strength, cost, and durability. Depending on the specific application, carbon steel screws can be treated with coatings to increase their corrosion resistance.

- Stainless Steel: For environments exposed to high humidity or corrosive substances, stainless steel screws are the preferred choice. Stainless steel offers superior resistance to rust and corrosion, making it suitable for use in outdoor, marine, or industrial environments.

- Alloy Steel: In high-strength applications, alloy steel screws may be used. These screws are made from steel alloys with added elements such as chromium or molybdenum, which enhance their strength and resistance to wear and tear.

Application Areas of ISO 14583

The screw with a semi-round head and Torx drive, as defined by ISO 14583, is widely used across various industries. Its unique design and high-performance specifications make it ideal for many different applications, particularly in settings where strength and durability are critical.

-

Automotive Industry: These screws are often used in the automotive industry for assembling parts of vehicles, including engine components, chassis, and other high-stress areas. The Torx drive ensures that these screws can be tightened with high torque without damaging the head, making them ideal for automotive production lines.

-

Construction: In construction, these screws are used for securing structural elements such as beams, frames, and panels. The high-strength classification ensures that the screws can hold up to heavy loads and external forces, contributing to the structural integrity of buildings.

-

Electronics: The semi-round head and Torx drive of the screw are particularly useful in the electronics industry, where precision and reliability are essential. These screws are used to fasten components within electronic devices, including computers, communication equipment, and consumer electronics.

-

Industrial Machinery: High-strength screws are widely used in the machinery industry, especially in heavy-duty equipment and manufacturing tools. The Torx drive allows for secure fastening that can handle high mechanical stresses without loosening, ensuring the smooth operation of machines.

In addition to these industries, the screw with a semi-round head and Torx drive is used in various other applications where secure fastening and high torque are required. Its versatility and durability make it a preferred choice for engineers and manufacturers seeking reliable fasteners for demanding applications.

These screws also help in reducing the chances of stripping, as the Torx drive allows for a better grip and more precise control during installation. This is especially important when dealing with screws that need to be tightened to a specific torque value, as the design minimizes the risk of tool slippage or damage to the screw head.

In conclusion, screws with semi-round heads and Torx drives according to ISO 14583 are a versatile and reliable choice for a wide range of industrial applications. Their strength, precision, and durability make them essential components in various sectors, from automotive to electronics and construction. Their ability to withstand high torque and their corrosion-resistant properties ensure that they provide secure, long-lasting connections in critical systems.