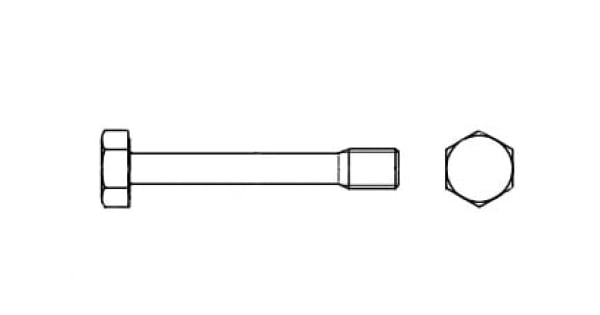

A DIN 7964 non-loosening screw is a specialized fastener designed for secure fixation of components, especially in conditions of vibration and dynamic loads. Its design incorporates a smooth shank section with a smaller diameter, preventing the screw from loosening unintentionally.

Strength Class DIN 7964

The strength class of a DIN 7964 screw determines its capacity to withstand tensile and shear loads. Typically, steel with a strength class of 8.8 or higher is used, ensuring a highly reliable joint.

Fastener Group DIN 7964

DIN 7964 screws belong to the group of special fasteners that provide additional component fixation. They are often used in conjunction with lock washers to enhance joint reliability.

Materials of Manufacture DIN 7964

The primary material for manufacturing DIN 7964 screws is carbon steel. To improve corrosion resistance, galvanized or stainless steels are used.

Application Area DIN 7964

DIN 7964 screws are widely used in various industries:

- Mechanical engineering: for fastening components of machines and mechanisms subject to vibration and dynamic loads.

- Automotive industry: for fastening chassis, engine, and suspension components.

- Instrument engineering: for connecting components of precision instruments.

- Construction: for fastening metal structures.

Advantages of using DIN 7964 screws:

- High reliability: due to its special design, the screw is securely fixed in the hole and does not loosen spontaneously.

- Vibration resistance: ideal for use in conditions of high vibration.

- Durability: made of strong materials, ensuring a long service life.

- Easy installation: installed with standard tools.

- Versatility: can be used in various industries.

DIN 7964 non-loosening screws are a reliable and effective fastening method in conditions with high demands for safety and reliability of connections. Their use prevents unwanted self-loosening and ensures the durability of structures.