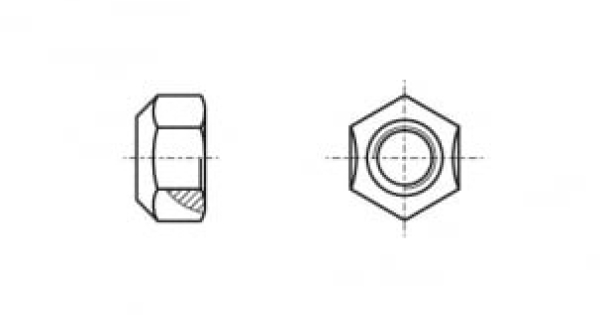

A self-contracting nut is a nut used in connection elements that are constantly exposed to dynamic loads, especially vibration, which can cause loosening. Contouring in ISO 10513 is achieved due to the design of the hole: it can be a narrowed edge of the hole, or a special metal locking ring, depending on the shape. When used in areas of high temperatures, it is better to choose ISO 10513.

Strength class ISO 10513

The strength class of an ISO 10513 nut is the maximum applied force at which the nut begins to fracture. ISO 10513 nuts are manufactured in strength classes 8 and 10. From strength class 8, the nut is considered high-strength. High-strength ISO 10513 should be purchased only from trusted suppliers. It is made of alloy steel and such bolts are used for critical projects where, in addition to high loads and static loads, the ISO 10513 nut is subjected to constant vibration. Such nuts will be especially relevant in bridge construction, instrumentation, and in structures that are located near objects subject to vibration.

Fastening group ISO 10513

Depending on the material of manufacture, ISO 10513 nuts are divided into groups:

- High-strength fasteners - nuts are made of steel of strength class 8 and above

- Stainless fasteners - nuts are made of stainless steel grades A2 and A4

Materials for the manufacture of ISO 10513 nuts

ISO 10513 is manufactured from the following materials

- Steel, which can be coated with hot-dip galvanized, yellow zinc, and black zinc.

- Stainless steel grades A2 and A4.

Applications for ISO 10513 nuts

ISO 10513 is used in

- mechanical engineering

- construction

- warehouse equipment,

- lifting equipment,

- agricultural machinery, tools, etc.