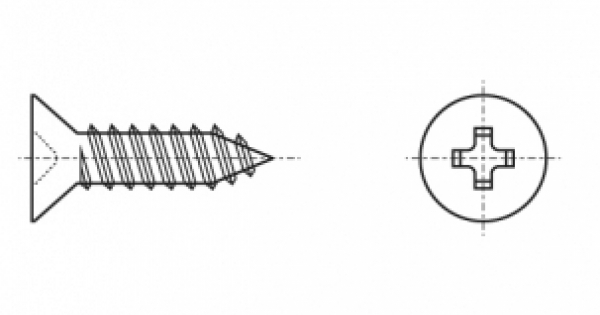

ISO 14586 is a popular fastener that is manufactured in accordance with the requirements of the ISO 14586 standards. Other commonly used names are self-tapping screws and self-tapping screws. These screws consist of a countersunk head with a PH cross-shaped slot. For screwing, special tools are used with a nozzle that is matched to the appropriate slot size.

Materials used to manufacture ISO 14586

ISO 14586 is available in the following materials:

- Steel, which can optionally be coated with zinc

- Stainless steel (A2, A4) does not need to be coated

Areas of application of ISO 14586

Due to their high technical characteristics and versatility, self-tapping stainless steel screws (ISO 14586) are widely used in various industries and activities to create strong, reliable and durable permanent connections. For example: in mechanical engineering, during the production, assembly and installation of furniture, installation of various hinged structures, in various construction, repair and finishing processes, in many economic sectors, in the production of agricultural equipment and installations, in everyday life, etc.

Basically, this fastener is used for load-bearing structures made of such materials as: various types of metal, wood, plywood, organite, etc. When working with these products, to fully immerse the hardware into the surface of the material, it is necessary to chamfer the countersunk heads.

When installing certain structures, for example, concrete, brick, plasterboard frames, etc., this fastener can act as a dowel.

It is convenient that when screwing countersunk screws into wood or plastic, there is no need to make preliminary holes in the materials. However, to connect thicker and stronger materials (metals), the holes must be prepared in advance.

The high quality of the steel and the sharpening of the tip and thread make it possible to screw in the screws without damaging the materials.