An ISO 1482 self-tapping screw is a versatile fastening element used to join various materials without the need for pre-drilling. Its design ensures a secure and strong connection.

Technical Characteristics of ISO 1482

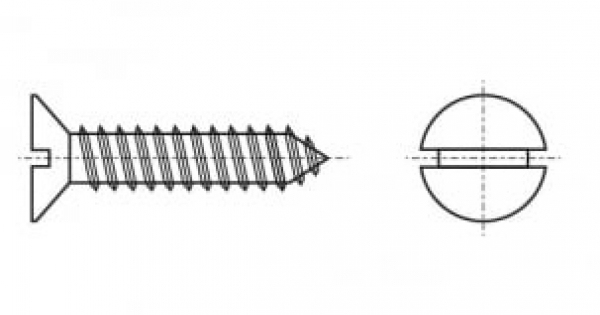

- Head: Countersunk, allowing the screw to be embedded in the material, providing a smooth surface.

- Slot: Straight, designed for use with flat-head screwdrivers.

- Thread: Metric, ensuring secure screwing into various materials.

- Point: Pointed, facilitating initial screwing.

Dimensions of ISO 1482 Self-Tapping Screw with Countersunk Head and Straight Slot

The dimensions of ISO 1482 screws are determined by the thread diameter and length. The range of sizes is quite wide, allowing you to choose the optimal option for each specific case. The ISO 1482 standard details the permissible diameters and lengths for different strength classes.

Strength Class ISO 1482

The strength class of ISO 1482 screws is determined by its ability to withstand loads. The ISO 1482 standard defines several strength classes, allowing you to select the screw according to the requirements of a specific application. Most commonly used are screws with a strength class of 4.8 and 8.8, which ensure a high reliability of the connection.

Fastener Group ISO 1482 Self-Tapping Screw with Countersunk Head and Straight Slot

ISO 1482 screws belong to the group of self-tapping fasteners. They are used to join various materials such as wood, metal, and plastic.

Materials for the Manufacture of ISO 1482

Carbon steel with a zinc or other type of protective coating is most commonly used for the production of ISO 1482 screws. Stainless steel and other special alloys can also be used for special operating conditions. The choice of material depends on the expected operating conditions and corrosion resistance requirements.

Scope of Application of ISO 1482 Self-Tapping Screw with Countersunk Head and Straight Slot

ISO 1482 screws are widely used in various industries:

- Construction: for fastening drywall, plywood, wooden elements.

- Furniture industry: for joining furniture parts.

- Automotive industry: for fastening upholstery, interior parts.

- Metal structures: for joining thin metal sheets.

Advantages of using ISO 1482 screws:

- Fast installation: Does not require pre-drilling.

- Reliability: Ensures a strong connection of various materials.

- Versatility: Can be used for both indoor and outdoor work.

- Economy: Relatively low cost.

The use of ISO 1482 screws allows you to quickly and efficiently perform various installation work, ensuring the reliability and durability of structures.