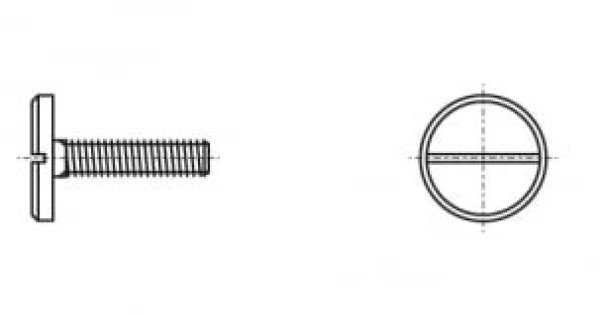

ISO 1665 is a clamping type fastener. It is made in the form of a rod with a metric thread and an enlarged head. The use of this screw makes it possible to obtain a quick-release connection characterized by a significant clamping force and a small protrusion above the surface.

Strength class ISO 1665

ISO 1665 screws are made of steel with a strength class of 5.8.

Fastening group ISO 1665

ISO 1665 screws are most often made of stainless steel and belong to the stainless fastener group.

Materials for the manufacture of ISO 1665 screws

ISO 1665 screws are made of the following materials:

- Steel with a strength class of 5.8, which can optionally be coated with zinc. Zinc (Plated) protects against corrosion if the fastener is to be used in aggressive environments.

- Stainless steel grade A1. Allows the use of fasteners at significant temperature changes and in aggressive and humid environments.

Applications for ISO 1665 screws

ISO 1665 screws are widely used in instrumentation and other industrial sectors. They are designed for quick-release fastening of parts made of thin-walled materials: the increased diameter of the head reduces the pressure on the material and prevents its deformation. ISO 1665 screws are widely used in instrumentation, mechanical engineering, automotive, and other industrial applications.