Technical Specifications of ISO 2341

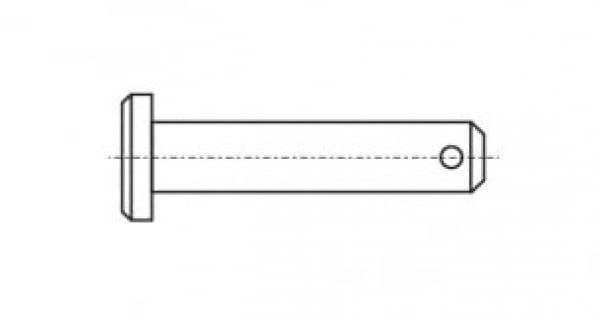

A low-head pin with a hole, corresponding (approximately) to the ISO 2341 standard, is a specialized type of fastener used to connect machine parts and mechanisms. Its primary difference from a standard cylindrical pin is the presence of a low head, which limits the height of the connection. This allows it to be used in confined spaces. The hole in the head is designed for securing with other elements, such as split pins or retaining rings.

Dimensions of ISO 2341 Low-Head Pin with Hole

The dimensions of such pins can vary depending on the specific manufacturer and application. They are typically determined by the pin diameter, its length, hole diameter, and head height. The exact dimensions are usually specified in the technical documentation for the specific product.

Strength Class of ISO 2341

The strength class of a pin defines its ability to withstand certain loads without failure. For low-head pins, high-strength materials like alloy steel are commonly used. The strength class may be indicated according to national or international standards, such as ISO.

Fastening Group of ISO 2341 Low-Head Pin with Hole

A low-head pin belongs to the group of positioning fasteners. It is used to fix parts in a specific position and prevent their rotation. The low head allows it to be used in narrow gaps where the application of a standard cylindrical pin is difficult.

Materials for Manufacturing ISO 2341

The following materials are commonly used to manufacture low-head pins:

- Alloy steel: Provides high strength, hardness, and wear resistance.

- Stainless steel: Used in aggressive environments where high corrosion resistance is required.

- Brass: Used for less loaded connections where good corrosion resistance is required.

Applications of ISO 2341 Low-Head Pin with Hole

Low-head pins are widely used in various industries:

- Mechanical engineering: for fixing machine parts and mechanisms in confined spaces.

- Instrument making: for assembling instruments and devices.

- Automotive industry: for fastening automotive parts.

- Aerospace industry: for connecting components of aircraft and helicopters.

Advantages of using low-head pins:

- Compactness: Can be used in confined spaces.

- Reliability: Provides a strong and reliable connection of parts.

- Versatility: Can be used in various constructions.

- Ease of assembly: Easy to install and remove.

A low-head pin with a hole is an important fastening element used in many industries. Its main advantage lies in its ability to be used in confined spaces. The choice of a specific pin depends on the requirements for strength, corrosion resistance, and operating conditions.