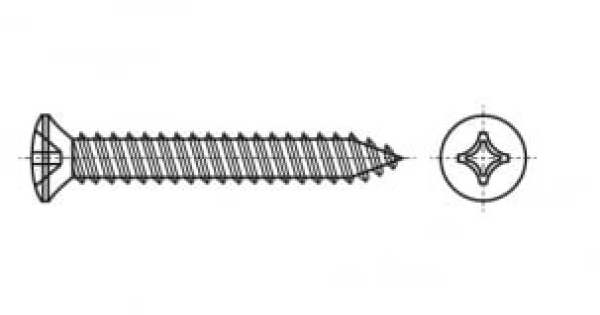

ISO 7051 is a self-tapping screw with a semi-recessed head, which can be used to connect sheet steel elements to pastic, as well as to fix various elements on sheet steel. The ISO 7051 standard specifies two end types, shape C and shape F. The first shape, C, indicates a sharp end, the second a blunt end, respectively, shape F. The differences don't end there. It is allowed to perform with two types of slots - cross (Ph) and posidrive (Pz).

Fastening group ISO 7051

ISO 7051 self-tapping screws are most often made of stainless steel and belong to the group of stainless fasteners.

Materials for the manufacture of self-tapping screws ISO 7051

Self-tapping screws ISO 7051 are made of the following materials:

- Steel, which is additionally coated with white and black zinc, which protects against corrosion, if the fasteners are intended to be used in aggressive environments.

- A2 and A4 stainless steel allows the use of fasteners at significant temperature changes and in aggressive and humid environments. The material does not need coating.

Scope of ISO 7051 self-tapping screws

The ISO 7051 self-tapping screw has become widely used in industry, as well as in construction. It is used for connecting structural elements, as well as for installation in wood, plastic without pre-drilling a hole, as well as in metal. but with pre-drilling.

A feature of ISO 7051 is additional slots at the end, which increase the drilling moment. Thus, the installation will be made even easier and faster.