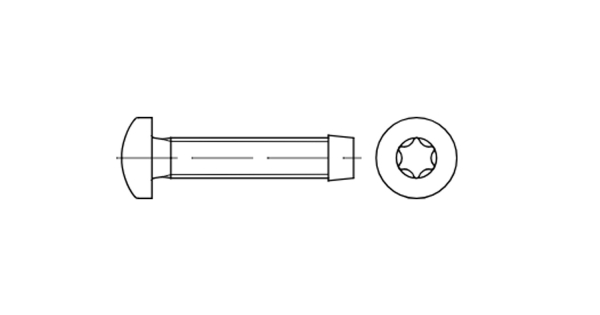

DIN 7500 C is a standard for self-tapping countersunk screws that specifies their dimensions and technical characteristics. Self-tapping countersunk screws have a special design with a tip that can cut threads in soft materials such as plastic, aluminum and light steel.

The main feature of self-tapping countersunk screws is that they can provide a secure connection without the need for nuts or washers. They are commonly used in construction and engineering applications where it is necessary to ensure a secure connection of parts made of soft materials.

ISO 7085 fastener group

ISO 7085 screws belong to the stainless steel fasteners group.

Materials for the manufacture of ISO 7085 screws

ISO 7085 screws are made of the following materials:

- Steel, which is additionally coated with zinc. Zinc (Plated) protects against corrosion if the fastener is to be used in aggressive environments.

- Stainless steel. Steel grade A2 allows the fasteners to be used at significant temperature changes and in aggressive and humid environments.

Applications for ISO 7085 screws

Self-tapping countersunk head screws in accordance with DIN 7500 C can be used in various industries, such as mechanical engineering, automotive, electronics, construction, furniture manufacturing, and others. They can be used to connect parts made of soft materials such as plastic, aluminum, light and medium steel.

Due to their design, self-tapping countersunk screws can easily and quickly cut threads in soft materials without the need for tools or additional fasteners. They can also provide a secure connection between parts without the need for nuts or washers, which reduces assembly time and costs.