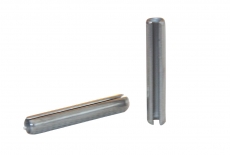

ISO 8752 is a spring-loaded threaded pin. It is a cylindrical, nearly closed rod that is used for fixed connection of various parts as well as for load transfer. The dimensional grid can be found in ISO 8752 pdf.

Materials of manufacture

The ISO 8752 pin is manufactured:

- Steel, which can be optionally coated with zinc and zinc plating

- Stainless steel grade A2

Where are ISO 8752 spring cylindrical pins used?

The main areas of application of the ISO 8752 pin are mechanical engineering, industrial engineering, and instrumentation. First, the parts to be fastened are installed and fixed in the same position, after which a hole for the pin is drilled in them, and then a spring pin is installed in this hole, which holds the parts together.

The scope of application of the ISO 8752 pin also directly depends on the material of manufacture and the coating of the product:

- Zinc coating on steel protects against corrosion if the fastener is to be used in aggressive environments

- Stainless steel, grade A2. The material is non-toxic and corrosion-resistant, which makes it suitable for use in the food and medical industries.