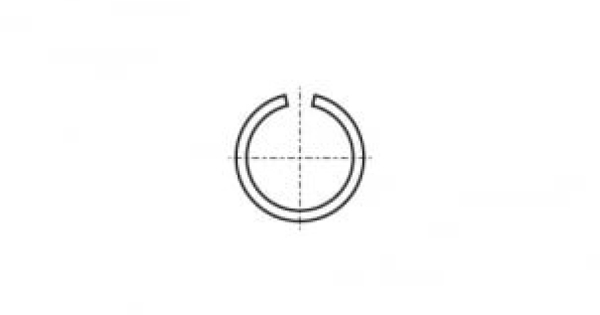

An external retaining ring DIN 7993 A is a small metal component used to secure other parts on shafts or in bores. It prevents these parts from accidentally shifting during the operation of mechanisms.

Technical Specifications DIN 7993 A

DIN 7993 A is an international standard that defines the dimensions, shape, and materials of retaining rings. This standard ensures that the ring meets specific quality requirements.

- Material: Typically steel with various coatings.

- Dimensions: The diameter, thickness, and width of the ring are defined by the DIN 7993 A standard.

- Accuracy Class: Ensures high manufacturing precision.

Manufacturing Material:

Retaining rings are usually made of steel. Steel is a very strong material that can withstand various loads. Sometimes, to protect against corrosion, steel rings are coated with special substances such as zinc or chromium.

Functions:

The retaining ring has a special shape that allows it to fit tightly against the part and the shaft. This creates a mechanical barrier that prevents the part from moving along the axis.

Applications:

Retaining rings are widely used in various industries:

- Mechanical engineering: For securing bearings, gears, couplings, and other parts.

- Automotive industry: For securing transmission parts, steering, and other components.

- Instrument making: For securing elements of precision instruments.

- Construction: For securing structural elements.

Advantages of using retaining rings:

- Reliability: Provides a secure fastening of parts.

- Durability: Made of durable materials.

- Ease of use: Easy to install.

- Versatility: Suitable for many types of connections.

Types of retaining rings:

There are several types of retaining rings that differ in shape and installation method:

- External: Installed in a groove on the shaft.

- Internal: Installed in a groove inside the hole.

- Split rings: Split rings that are easy to install and remove.

The external retaining ring DIN 7993 A is an important fastening element that ensures reliable securing of parts. Due to its characteristics and wide range of applications, retaining rings are widely used in various industries.