Sure! Here's the English translation of your text:

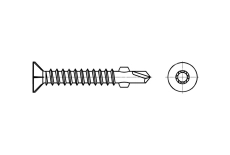

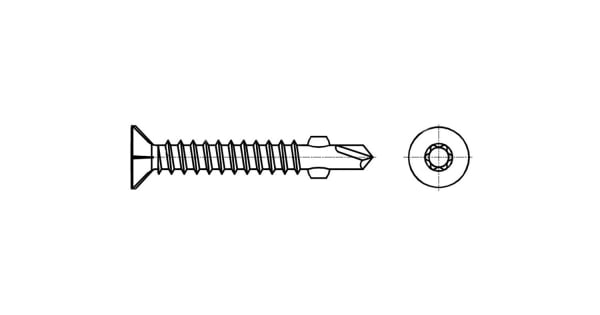

Countersunk Head Milling Screw with Drill Bit ISO 15482

The countersunk head milling screw with drill bit ISO 15482 is a specialized fastener designed for installation in metal and hard materials without pre-drilling. Thanks to the integrated drill tip and head design, it ensures quick installation with minimal effort. The countersunk head allows the screw to be fully embedded into the material, creating a smooth surface.

The ISO 15482 standard defines the geometric and mechanical requirements for such screws. This fastener performs multiple functions simultaneously: drilling, threading, and fastening, which significantly reduces assembly time.

Technical Specifications ISO 15482

Key parameters of the screw:

-

Shape: cylindrical body with threading, countersunk head with cross or TORX drive, drill tip

-

Material: hardened carbon steel or stainless steel

-

Coating: electro-galvanized zinc or phosphating for corrosion protection

-

Design features: drill tip enables drilling without the need for a pilot hole

Thanks to the drill tip, the ISO 15482 screw is suitable for mounting in thin metal, aluminum, composites, and plastic. The use of a countersunk head ensures an aesthetic fastening appearance without protruding elements.

Strength Class of the Countersunk Head Milling Screw with Drill Bit ISO 15482

The ISO 15482 standard does not classify screws by numerical strength classes like bolts, but their operational capabilities depend on material properties and heat treatment:

-

Hardened carbon steel — provides high hardness and thread strength

-

Stainless steel — optimal for wet and aggressive environments, although lower hardness

-

Heat treatment — applied to increase hardness and wear resistance of the threads and drill tip

Screws of this type must withstand significant axial load and torque without deformation or failure.

Fastener Group ISO 15482

According to fastener classification, the ISO 15482 screw belongs to:

-

Self-drilling screws with drill tip

-

Countersunk head fasteners for flush mounting

-

Elements for connections without pre-drilled holes

Primary functions:

-

Creating a reliable connection between sheet metals or metal and plastic

-

Reducing assembly time through combined drilling, threading, and fastening actions

-

Eliminating the need for nuts or anchors

-

Use without additional drilling

Materials of Manufacture for the Countersunk Head Milling Screw with Drill Bit ISO 15482

Materials for ISO 15482 screws are selected based on strength, deformation resistance, and corrosion resistance. Commonly used materials include:

-

Carbon steel — for general use, providing high hardness after heat treatment

-

Stainless steel — for humid environments, chemical exposure, or outdoor mounting

-

Alloys with chromium or nickel additions — for enhanced resistance to aggressive conditions

Surface treatments increase corrosion resistance:

-

Zinc plating — the most common coating for domestic and industrial use

-

Phosphating — improves adhesion for paint or varnish coatings

-

Uncoated — allowed for dry indoor use or when using stainless steel

Material choice depends on operating conditions, base material type, load, and connection durability requirements.

Application Areas ISO 15482

ISO 15482 screws are widely used in various industries requiring reliable and fast connections without pre-drilling:

-

Metal structures — joining sheet metal, mounting ventilation and cladding components

-

Construction — fastening facade panels, profiles, sandwich panels, sheathing

-

Window and door manufacturing — mounting elements into aluminum or steel frames

-

Automotive industry — auxiliary fastening of panels, body parts, metal brackets

-

Household appliances — fastening metal or plastic parts to device housings

-

Agricultural machinery — mounting attachments and structures in dirty and vibrating environments

These screws are especially effective in serial and automated production where fast assembly, connection stability, and lack of preparatory work are crucial.