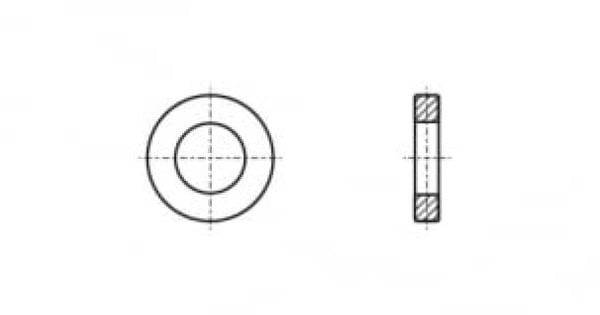

An ISO 7090 pin washer is a specialized type of fastener used to increase the strength and reliability of connections. It plays a crucial role in various industries by ensuring even load distribution and preventing premature wear of components.

How it works

The washer is installed along with a pin (axle) in a hole in the component. Due to its shape and greater thickness, it increases the bearing surface on the component's surface, allowing for even load distribution and reducing pressure on the material. This, in turn, prevents deformation of the component and extends its service life.

Technical characteristics

- Material: Most commonly made of steel, but other materials such as stainless steel, brass or aluminum can be used depending on operating conditions.

- Accuracy class A: This means that the washer is manufactured with high precision, ensuring a reliable connection of parts.

- Coating: To protect against corrosion and improve appearance, washers can be coated with zinc, cadmium or other materials.

- Dimensions: The inner diameter (for the pin), outer diameter and thickness of the washer are regulated by the ISO 7090 standard.

Advantages of using ISO 7090 washers

- High strength: Thanks to the use of steel and precision manufacturing, washers provide a reliable fixation of parts.

- Increased bearing surface: Reduces pressure on the part, preventing its deformation.

- Prevention of rotation: Fixes parts more securely, preventing them from loosening on their own.

- Corrosion protection: The coating protects the washer from moisture and aggressive environments.

- Durability: Due to the high quality of materials and precision manufacturing, washers have a long service life.

- Versatility: Can be used in various industries and for different types of connections.

Applications

ISO 7090 washers are widely used in various industries:

- Mechanical engineering: For fastening parts of machines and mechanisms, such as bearings, gears, shafts.

- Automotive industry: For connecting suspension elements, steering and other components.

- Instrument making: For fixing parts of precision instruments.

- Construction: For fastening metal structures.

Choosing washers

When choosing an ISO 7090 pin washer, the following factors should be considered:

- Material of the parts being connected: The choice of washer material depends on the material of the parts it comes into contact with.

- Load: It is necessary to select a washer with sufficient load-bearing capacity.

- Operating conditions: Consider temperature, humidity, and the presence of aggressive environments.

ISO 7090 pin washers are an indispensable fastening element in many industries. Thanks to their technical characteristics and advantages, they ensure the reliability, durability and accuracy of connections. The use of ISO 7090 washers allows to improve the quality and safety of products, as well as reduce costs for repair and maintenance.