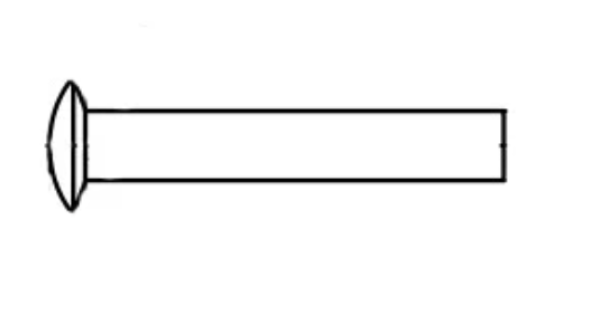

A round-head rivet with a countersunk head according to GOST 10301-80 is a special type of fastener used to join parts by deformation. It consists of a cylindrical shank with a head on one side and a rivet part on the other. During installation, the rivet part is flattened with a hammer, ensuring a secure fastening.

Strength class GOST 10301-80

The strength class of a rivet determines its ability to withstand loads. For rivets according to GOST10301-80, the strength class of the material from which they are made is usually indicated (for example, steel 3, steel 5).

Fastening group Round-head rivet with a countersunk head according to GOST 10301-80

Rivets belong to the group of riveted joints. They are used where it is impossible or impractical to use other types of fasteners (screws, bolts).

Materials of manufacture GOST 10301-80

Most often, various grades of steel are used to manufacture rivets according to GOST 10301-80. The choice of material depends on the operating conditions and the required strength of the joint. Aluminum, copper, and other metals can also be used.

Scope of application GOST 10301-80

Round-head rivets with a countersunk head according to GOST10301-80 are widely used in various industries:

- Mechanical engineering: for joining thin sheets, fastening parts to frames, and manufacturing housings.

- Automotive industry: for joining body elements, upholstery, and fastening interior parts.

- Aviation: for joining light alloys.

- Construction: for fastening roofing materials, facade panels.

- Furniture industry: for joining furniture parts.

Advantages of using rivets according to GOST 10301-80:

- Easy installation: does not require special tools, only a hammer.

- Reliable connection: provides a strong and durable connection of parts.

- Aesthetics: after installation, a small head remains on the surface.

- Ability to connect parts made of different materials.

- No need for threads.

Round-head rivets with a countersunk head according to GOST 10301-80 are a universal and reliable type of fastener widely used in various industries. Their use allows simplifying and accelerating the assembly process, ensuring high strength and aesthetics of joints.