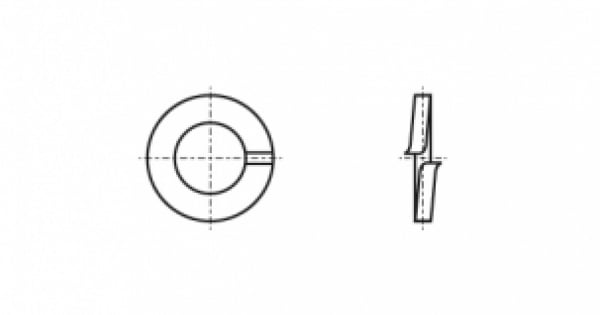

DIN 127 is a fairly simple fastener that can withstand strong load shocks and act as a locking element. It looks like a single coil of a flat spring. That is why this fastener is called a spring washer. The trouble-free operation of this element is ensured by the fact that the gap of the part diverges in the opposite direction from the direction of rotation of the nut, which prevents it from spontaneously unwinding.

Materials for the manufacture of DIN 127 washers

DIN 127 is manufactured in the following materials:

- Steel, which can be additionally coated with hot-dip, ordinary, and plate zinc.

- Stainless steel (A2, A4) does not require coating.

Areas of application of the groover

The main feature of these grippers is that they are designed for bolts and studs with a strength not exceeding 5.8. They are used to fasten enclosure covers or protective shields, and are also used to create various metal structures. For example, warehouse or commercial shelving, sectional fences.

For production purposes, growers made of bronze and galvanized steel are used. This allows them to be used both outdoors and indoors.

In addition, the scope of application directly depends on the material of manufacture and the coating of the product:

- Galvanized steel provides good corrosion protection if the fastener is to be used in aggressive environments.

- Stainless steel allows the fasteners to be used at significant temperature fluctuations and in aggressive and humid environments.

- Bronze-coated fasteners are made of steel whose surface has been chemically treated. Compared to galvanized or zinc-passivated fasteners, its surface is less resistant to corrosion and should only be used indoors. Bronze-coated fasteners are brown in color, which makes them ideal for restoration work on furniture or antique wood.