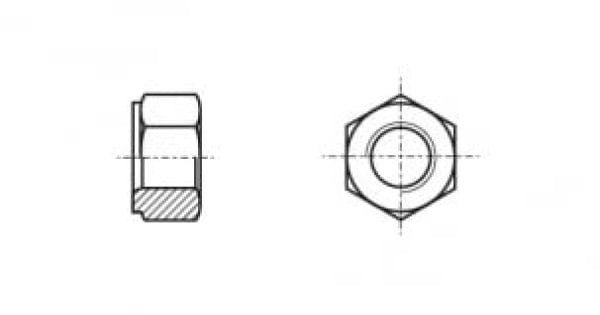

The DIN 2510-5 NF hexagonal nut is one of many nuts that comply with the DIN 2510 standard. This standard describes nuts with an internal thread and high strength for use in fasteners subject to high loads and temperatures. Hexagonal nut DIN 2510-5 NF has a hexagonal shape, which makes it easy to tighten with a wrench. The NF in the description of the nut means that its thread has a finishing accuracy, which means that it has a higher thread accuracy than conventional nuts. This ensures a stronger and more reliable fastening.

Materials for the manufacture of nuts DIN 2510-5 NF

Hexagonal nuts DIN 2510-5 NF can be made of different materials depending on the specific requirements for strength, corrosion resistance, temperature conditions and other operating factors. The main materials for the manufacture of DIN 2510-5 NF nuts include

- Carbon steel: This is the main material used for the manufacture of nuts. Carbon steel has high strength and corrosion resistance, which ensures their efficiency and durability.

- Alloy steel: Nuts made from this steel have higher strength and corrosion resistance than carbon steel. Alloy steel contains additional elements, such as chromium, molybdenum, and nickel, which enhance its physical characteristics.

- Stainless steel: This material is used for the manufacture of nuts to be used in aggressive environments containing acids, salts, water, etc. Stainless steel is highly resistant to corrosion, which ensures reliable operation of nuts in such conditions.

- Other materials: DIN 2510-5 NF nuts can also be made of other materials such as titanium, brass, aluminum, etc., depending on the requirements of the specific application.

The choice of material for the manufacture of the nut depends on the specific needs and conditions of its operation.

Areas of application of nuts DIN 2510-5

Hexagonal nuts DIN 2510-5 NF have a wide range of applications, especially in heavy and critical industries where the requirements for reliability and structural strength are very high. Some of the areas of application include:

- Mechanical engineering: DIN 2510-5 NF nuts are used in the mechanical engineering industry to connect and fasten various parts of machines, equipment and mechanisms.

- Energy: In the energy industry, DIN 2510-5 NF hex nuts are used to fasten various elements in power plants, the oil and gas industry, wind power and other areas.

- Transportation: DIN 2510-5 NF nuts are widely used in transportation, including the automotive, railroad and aviation industries, to connect and fasten various vehicle parts.

- Construction: In the construction industry, DIN 2510-5 NF nuts are used to fasten various structural parts, such as steel pipes, metal structure fasteners, etc.

- Chemical and oil refining industry: Hexagonal nuts DIN 2510-5 NF are used in the chemical and oil refining industry to fasten various parts that are exposed to aggressive media.

Therefore, DIN 2510-5 NF nuts have a wide range of applications and are used in various industries where the requirements for strength and reliability of fastening are high.