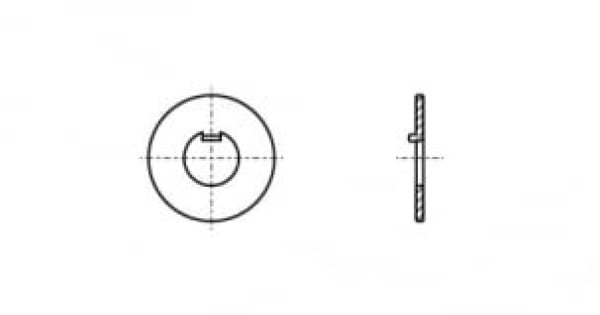

DIN 462 Washer with internal lug is a fastener used in conjunction with a spline nut to DIN 1804. It is installed between the part to be clamped on the shaft (bearing, bushing) and the spline nut. The inner foot slides into a longitudinal groove to secure it against turning, and the outer part of the washer bends into the groove of the spline nut when it is tightened to the end, making it impossible to loosen it.

DIN 462 fastening group

DIN 462 washers are most often made of stainless steel and belong to the stainless fastener group.

Materials for the manufacture of DIN 462 washers

DIN 462 washers are made of the following materials:

- Steel, which can optionally be coated with zinc. Zinc (Plated) protects against corrosion if the fastener is to be used in aggressive environments.

- Stainless steel grades A2 and A4. Allows the use of fasteners at significant temperature changes and in aggressive and humid environments.

Scope of use of the DIN 462 washer

DIN 462 is used in shipbuilding, industry, and construction to securely fix fasteners to structural elements. The internal tendril prevents self loosening of threaded connections under dynamic impact and vibration. It can be used with both dynamic and static loads. Washers with an internal lug are used as an auxiliary fastening element in combination with bolts or nuts to ensure the strength and reliability of connections.