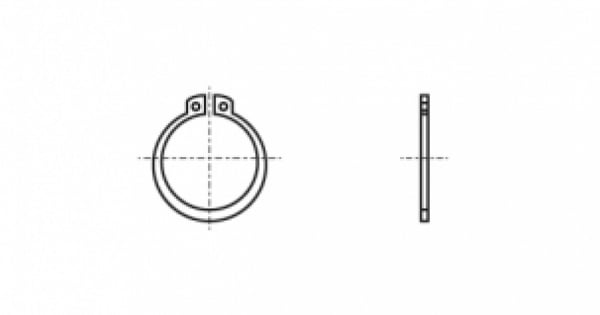

A circlip according to DIN 471 is an eccentric fastener that is used on a shaft or in a bore. This element prevents spontaneous displacement of the mechanism elements relative to each other, which is especially important some time after installation. This increases the reliability of the structure.

DIN 471 fastening group

DIN 471 is primarily made of stainless steel and belongs to the stainless steel fastener group.

Materials of manufacture:

The retaining ring DIN 471 is primarily made of:

- Steel, which can be additionally coated with zinc plating

- Stainless steel A2 as well as grade 1.4532 (austenitic)

Scope of application of circlips DIN 471

The circlip DIN 471 is a fastener that has a rather narrow scope of application. Its main areas of application are areas where there are structures with shafts.

For example:

- Mechanical engineering

- Automotive industry

- Instrumentation industry

- Construction.

The most common use is in the automotive industry. DIN 471 is indispensable both for engine repairs with bearings and for installing bearings in various modifications. They are mounted in a groove for more reliable fixation of bearing elements and eliminate defects in the profiling of the cage. DIN 471 limits the mobility of bearings on the axis. Read more about the dimensions in din 471 pdf.

The scope of DIN 471 also directly depends on the material of the fastener:

- Zinc-coated steel is less susceptible to corrosion if DIN 471 is to be used in aggressive environments.

- Stainless steel. Steel grade A2 makes it possible to use DIN 471 at significant temperature fluctuations and in aggressive and humid environments.