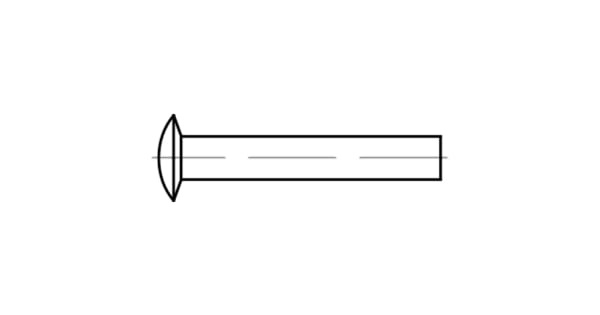

DIN 662 is a standard for semi-countersunk hammer rivets used to join parts in the metalworking and other industrial sectors. This type of rivet consists of a tubular body with a disc head at one end and a countersunk head at the other end. They are installed using a special tool - a rivet hammer. When the rivet is installed, its tubular part increases in diameter, which ensures a tight connection of the parts.

Fastening group DIN 662

Depending on the material of manufacture, DIN 662 rivets are divided into groups:

- Aluminum fasteners

- Copper fasteners

Materials for the manufacture of DIN 662 rivets

DIN 662 rivets are made of the following materials:

- Steel

- Copper

- Aluminum

The field of application of DIN 662 rivets

DIN 662 countersunk head rivets are widely used in the metalworking and other industrial sectors to join parts. The use of this type of rivet can be useful in cases where it is necessary to connect parts that cannot be welded or glued, or when it is necessary to ensure maximum strength of the connection under high loads.

Typical applications for DIN 662 rivets include

- assembling metal structures and various products made of steel, aluminum and other metals;

- repair of cars and other vehicles;

- production of furniture and other wood products;

- manufacturing of containers and other metal structures;

- manufacture of equipment and machinery for various industries.