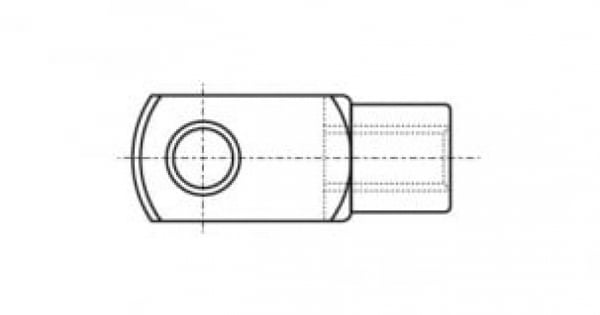

A fork head is a specialized type of fastener that has a distinctive fork-like shape at one end. This shape allows for the creation of strong and reliable connections, especially in places where additional fixation or adjustment is needed.

Construction and Materials

Fork heads can have various designs depending on their intended use. They are usually made of metal, such as steel or stainless steel, which provides high strength and durability. Additionally, other materials like brass or plastic can be used for specific applications.

Operating Principle

A fork head works on the principle of engagement. The fork is inserted into a hole or slot and is fixed in place by friction forces and material deformation. For additional fixation, nuts, washers, or other fasteners can be used.

Advantages of Using Fork Heads

- Reliability: Fork connections are characterized by high strength and resistance to vibrations.

- Versatility: Fork heads can be used in various industries and construction.

- Easy installation: No special tools are required to install a fork head.

- Adjustability: Some types of fork heads allow for adjustment of the tightening force.

Areas of Application

Fork heads are widely used in industries such as:

- Mechanical engineering: for fastening machine parts and mechanisms.

- Automotive industry: for fixing body elements and chassis components.

- Construction: for fastening structures made of wood, metal, and other materials.

- Furniture industry: for joining furniture parts.

DIN 71752 G Standard

The DIN 71752 G standard likely defines the specific technical characteristics of the fork head, such as dimensions, tolerances, materials, and quality requirements. For more detailed information on this standard, it is recommended to consult the relevant technical documentation.