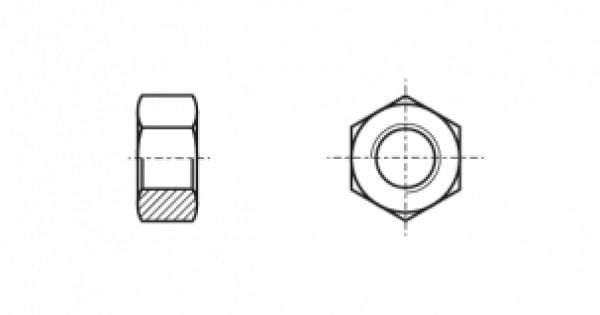

Din 934 (iso 4032) is the most common hexagonal nut. This nut is used to create high-strength detachable connections of metal parts and is used in conjunction with bolts and screws. The DIN 934 nut has six faces with a thread (metric or inch) on the inside. To fasten a DIN 934 nut, use wrenches of the appropriate size.

DIN 934 strength class

DIN 934 nuts are manufactured in strength classes 5, 6, 8, 10, 12. A strength class is a 100-fold reduction in the minimum strength of a bolt, which can be paired with a metal product to withstand normal loads. That is, even the minimum strength class of a DIN 934 nut can withstand more than 500 MPa.

Fastening group DIN 934

Depending on the material of manufacture, DIN 934 nuts are divided into:

- High-strength fasteners

- Stainless steel fasteners

- Polyamide fasteners

- Brass fasteners

- Copper fasteners

- Aluminum fastener

- Materials of manufacture of DIN 934 nut

The DIN 934 nut is widely used in construction equipment: bulldozers, cranes, excavators; power and industrial units: turbines, pumps, power generators, metalworking machines; trucks and agricultural machinery: trailers, semi-trailers, tractors, tractors.

DIN 934 nuts are used in conjunction with bolts or screws to create a secure threaded connection.

The scope of application also directly depends on the material of the nut:

- Galvanized steel offers good corrosion protection if the fastener is to be used in an aggressive environment.

- Brass is used if the system is subjected to frequent dynamic, vibration loads.

- Stainless steel allows the fasteners to be used at significant temperature changes and in aggressive and humid environments.

- Polyamide withstands mechanical shocks, does not crack or break at the permissible load factor.

- Copper is resistant to corrosion in dry air, fresh and salt water, alkaline solutions, organic acids, alcohols, and phenolic resins.

- Aluminum, due to the deformation of mild steel, seals the joint well.