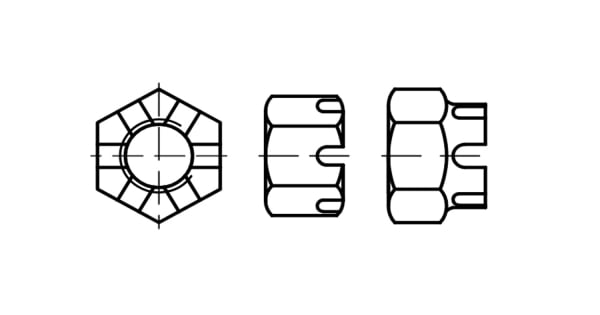

DIN 935 is a castellated nut used on all kinds of axles and shafts subject to vibration and dynamic loads. Holes are drilled in these axles into which cotter pins are inserted after tightening the nut, which in turn pass through vertical slots in the nut. This allows the nut to be securely fastened and prevents it from loosening during vibration.

Strength class DIN 935

The strength class of a DIN 935 nut is the maximum applied force at which the nut begins to fracture. DIN 935 nuts are manufactured in strength classes 6 to 10. From strength class 8 onwards, the nut is considered high-strength.

DIN 935 fastening group

The nuts are divided into groups according to their material of manufacture:

- High-strength fasteners - nuts made of steel of strength class 8 and above

- Stainless fasteners - nuts made of stainless steel.

Materials for the manufacture of DIN 935 nuts

DIN 985 is manufactured in the following materials:

- Steel, which can optionally be coated with plain (white) zinc.

- Stainless steel (A2, A4) does not need to be coated.

Areas of application for DIN 935 nuts

The DIN 935 nut is used in almost all industries. Hexagonal slotted nuts are often used in furniture production.