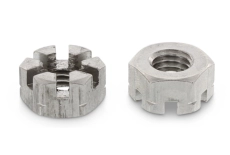

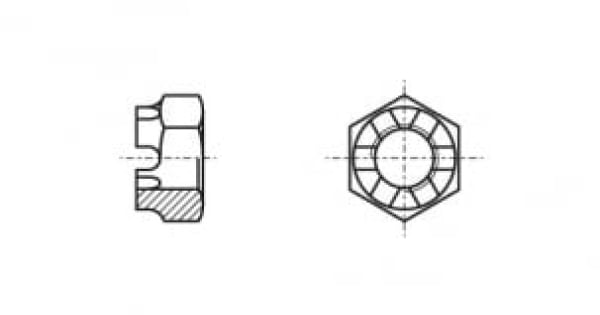

DIN 937 Low crown nuts or union nuts are nuts that are used on various types of axles and shafts where vibratory and dynamic loads are generated. Holes are drilled in these axles into which cotter pins are inserted after tightening the nut, which in turn pass through vertical slots in the nut. This ensures that the nut is securely fastened and prevents it from loosening during vibration.

DIN 937 fastening group

The DIN 937 low hexagon nut is most often made of stainless steel and belongs to the stainless steel fastener group.

Materials for the manufacture of DIN 937 nuts

DIN 937 low hex nut is made of the following materials:

- Steel, which can be coated with zinc to protect against corrosion if the fastener is to be used in aggressive environments.

- Stainless steel. Steel grades A2 and A4 allow the fasteners to be used at significant temperature extremes and in aggressive and humid environments.

Application range of DIN 937 nuts

All nuts of this type are designed for use with cotter pins. The product has six radially arranged slots (the number of slots can be increased or decreased depending on the size) and a cylindrical belt for metric thread diameters over 10 mm. Up to this size, nuts are made without a belt and are called slotted nuts. This ensures a secure fit and high vibration resistance, which protects the nut from shifting.