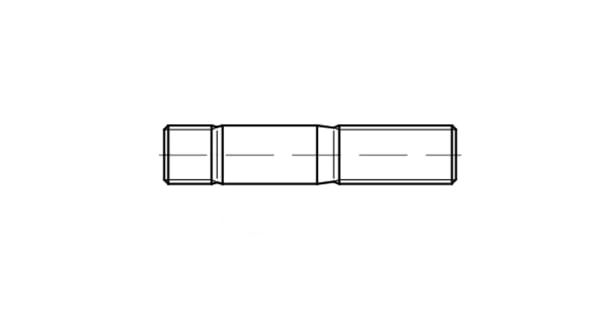

The DIN 938 stud is a threaded connection part with brought together ends, which is used to connect parts of machines and mechanisms. DIN 938 belongs to the group of studs with a thread diameter tolerance of 1d, which means that the thread diameter of the stud may differ from the nominal value by +/- 1 thread diameter. For example, if the nominal thread diameter of a DIN 938 thread is M10, then the thread diameter tolerance 1d is M10 +/- 0.1 mm. Thus, the actual thread diameter can be between M9.9 and M10.1 mm.

Strength class DIN 938

The strength class of a Din 938 stud is the maximum applied force at which the stud begins to fracture. Din 938 studs are manufactured in strength classes from 5.6 to 8.8. From strength class 8.8, the stud is considered high-strength.

DIN 938 fastening group

Depending on the material of manufacture, DIN 938 studs are divided into groups:

- Stainless fasteners

- High-strength fasteners

Materials for the manufacture of DIN 938 studs

DIN 938 studs are made of the following materials:

- Steel with a strength class of 5.6 to 8.8, which can optionally be coated with zinc. Zinc (Plated) protects against corrosion if the fasteners are to be used in aggressive environments.

- Stainless steel grades A2 and A4. The steel grade allows the fasteners to be used at significant temperature fluctuations and in aggressive and humid environments.

Application range of DIN 938 studs

DIN 938 studs are used in such industries as the automotive industry, instrumentation, and large studs are also actively used in construction, in the installation of metal structures and wooden elements.