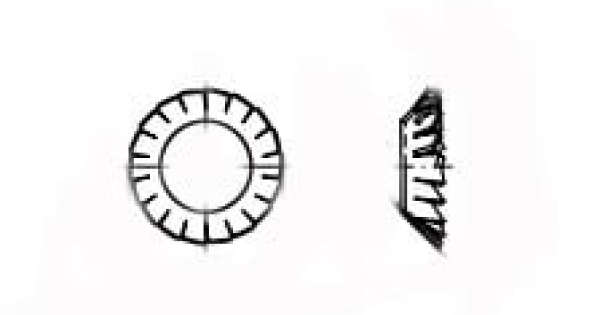

Washers DIN 6797 V are an integral part of many fastening connections. They serve to distribute the load on the surface, preventing material damage and ensuring a more reliable connection.

Technical Specifications of DIN 6797 V

The DIN 6797 V washer has the shape of a flat ring with an inner hole corresponding to the diameter of the bolt. The thickness of the washer depends on its diameter and purpose. The main technical characteristics that determine the dimensions and shape of the washer are standardized according to DIN 6797 V.

Strength Class of DIN 6797 V

The strength class of the DIN 6797 V washer indicates its ability to withstand certain loads without deformation or failure. It is closely related to the strength class of the bolt it is used with. The higher the strength class, the greater the loads the washer can withstand.

Fastener Groups of DIN 6797 V

Like other fasteners, DIN 6797 V washers are divided into groups depending on the material of manufacture and application:

- Steel washers: The most common type, used in a wide range of applications.

- Stainless steel washers: Used in aggressive environments requiring corrosion resistance.

- Brass washers: Applied in electrical engineering and where high electrical conductivity is needed.

- Washers made of other materials: Designed for special applications (e.g., Teflon washers to reduce friction).

Materials Used for DIN 6797 V

The primary materials for manufacturing DIN 6797 V washers include:

- Steel: Typically carbon steel or alloy steel.

- Stainless steel: A2, A4 grades.

- Brass: High corrosion resistance and good machinability.

- Other metals and alloys: Depending on specific requirements.

Application Areas of ISO 7091 DIN 6797 V Washers

DIN 6797 V washers are widely used in various industries:

- Mechanical engineering: For fastening machine parts and mechanisms.

- Construction: For securing metal structures.

- Automotive industry: For fastening body parts and other components.

- Electrical engineering: For fastening electrical connections.