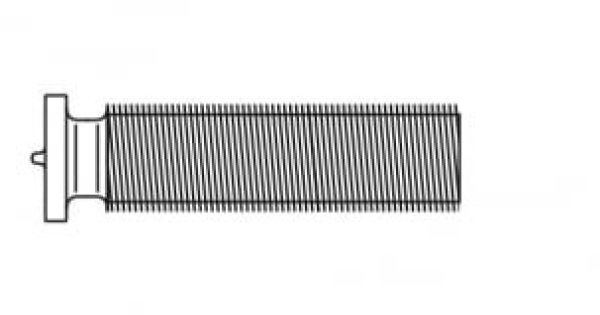

An ISO 13918 welding stud is a specialized fastener used to create strong and durable connections between various materials. It has a cylindrical shape with a threaded end on one side and a special tip for welding on the other. This standard defines the exact dimensions, materials, and quality requirements for the products.

Key characteristics:

- Diameter: Determines the thickness of the thread and the diameter of the stud head.

- Length: The total length of the stud, including the threaded part and the welding tip.

- Thread pitch: The distance between adjacent threads.

- Material: Typically made of steel, but other materials such as stainless steel or brass can be used.

- Welding tip: A special shape of the stud end that ensures a reliable weld to the base.

Strength Class ISO 13918

The strength class of an ISO 13918 welding stud determines its ability to withstand loads without deformation or failure. It depends on the material and the diameter of the stud. The choice of strength class depends on the specific operating conditions.

Fastener Group: ISO 13918 Welding Stud

ISO 13918 welding studs belong to the group of welding fasteners. They differ from ordinary screws in that they are installed by welding to the base. This provides a much stronger connection than using nuts or other mechanical fasteners.

Materials

The most common materials used for manufacturing ISO 13918 welding studs are:

- Steel: Provides high strength and rigidity.

- Stainless steel: Used in aggressive environments where high corrosion resistance is required.

- Brass: Used for studs that operate in high humidity conditions.

Application of ISO 13918

ISO 13918 welding studs are widely used in various industries:

- Mechanical engineering: For connecting machine parts and mechanisms, creating frames and structures.

- Automotive industry: For fastening body elements, suspension, and other components.

- Construction: For fastening metal structures, creating fastening elements.

- Electrical engineering: For fastening electrical components.

ISO 13918 welding studs are an indispensable element in many industries. Due to their technical characteristics and versatility, they are widely used to create strong and reliable connections. The choice of a specific type of stud depends on the requirements of a particular application.