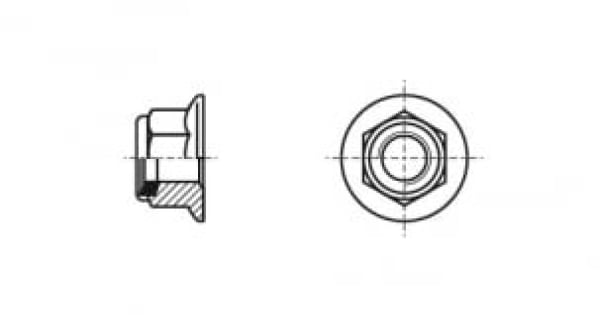

ISO 12125 A flanged nut is a fastener that creates a split threaded connection with an increased contact area, which allows for both redistribution of pressure on the material and a larger friction patch to prevent loosening, and is used when nuts are used to secure parts to grooves along which the part can move. ISO 12125 has a polyamide ring in its design, which makes it self-contracting.

Strength class of ISO 12125

The strength class of an ISO 12125 nut is the maximum applied force at which the nut begins to fracture. ISO 12125 nuts are available in strength classes 8 and 10. Only buy high-strength ISO 12125 from trusted suppliers. It is made of alloy steel and such nuts are used for critical projects where, in addition to high loads and static loads, the ISO 12125 nut is subjected to constant vibration.

ISO 12125 fastener group

Depending on the material of manufacture, ISO 12125 nuts are divided into groups:

- Stainless fasteners - fasteners made of stainless steel

- High-strength fasteners - fasteners made of steel of strength classes 8 and 10.

Materials for the manufacture of ISO 12125 nuts

ISO 12125 nuts are made of the following materials:

- High-strength structural alloy steel of strength classes 8 and 10. The high strength class allows the nuts to be used in highly loaded connections. Which can be additionally coated:

- Zinc protects against corrosion if the fasteners are to be used in aggressive environments.

- Zinc plating protects against corrosion if the fasteners are to be used in aggressive environments.

- Delta-Mks - zinc dispersed anti-corrosion coating systems. They outperform all traditional types of coatings in terms of corrosion resistance. Increase the service life of fasteners in urban environments by 5 times.

- Stainless steel grades A2 and A4

Applications for ISO 12125 nuts

The ISO 12125 nut is used in production where there is a slightly acidic environment, such as shipbuilding and the space industry. Hexagonal nuts ISO 12125 are most often used in high-strength connections.