ISO 10512 is not a standard that describes high-strength self-locking nuts. In fact, such a standard does not exist. You might be thinking of another standard, such as ISO 7040, which does indeed pertain to high-strength self-locking nuts.

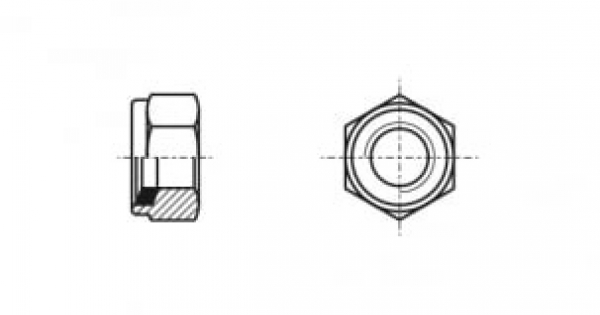

High-Strength Self-Locking Nuts: General Information

A high-strength self-locking nut is a special type of fastener used to create strong and reliable connections. Its design incorporates a mechanism that prevents it from loosening under vibration, dynamic loads, or other external factors. This makes such nuts indispensable in many industries where the reliability of connections is critical.

Operating Principle

The self-locking properties of the nut are achieved through various mechanisms. The most common are:

- Internal cone: A special cone inside the nut cuts into the bolt thread when tightened, creating additional friction and preventing self-loosening.

- Friction elements: In some nut models, friction elements are used that deform upon tightening and press tightly against the thread walls.

- Plastic inserts: Some nuts have plastic inserts that deform when tightened and provide additional friction.

Materials

Various materials are used to manufacture high-strength self-locking nuts, with the most common being:

- Carbon steel: Provides high strength and hardness but is susceptible to corrosion.

- Stainless steel: Has high corrosion resistance but may be less strong than carbon steel.

- Alloyed steels: Combine high strength, hardness, and corrosion resistance.

Strength Classes

The strength class of a nut indicates its ability to withstand certain loads without failure. The higher the strength class, the greater the load the nut can withstand. For high-strength self-locking nuts, strength classes 8.8, 10.9, and 12.9 are typically used.

Applications

High-strength self-locking nuts are widely used in various industries:

- Automotive industry: For fastening engine parts, chassis components, and body panels.

- Mechanical engineering: For connecting machine parts and mechanisms operating under vibration conditions.

- Aviation industry: For fastening aircraft parts.

- Construction: For fastening metal structures.

Advantages of Use

- Reliability: Prevents self-loosening in demanding operating conditions.

- Safety: Reduces the risk of accidents and injuries related to loose fasteners.

- Durability: Ensures a long service life of connections.

- Versatility: Can be used in various industries.

High-strength self-locking nuts are an essential fastening element in many industries. Due to their technical characteristics, they ensure the reliability and safety of connections, which is especially important in conditions of increased vibration and dynamic loads.