Rivet hardware is made of metal and is used to connect two or more parts together. The main types of riveted metal products include the following:

- Extraction rivets, which are also divided into: with a hidden edge, and enlarged.

- Threaded rivets come with a hidden or enlarged shoulder.

- Hammer- are the only rivets that require access from the other side of the material.

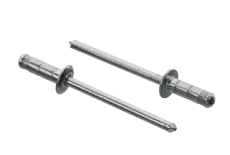

Exhaust rivets

Pull rivets (or flat rivets) are a type of rivet used to connect two parts, usually metal, between which there is no access from both sides. They consist of two parts: a head and a cog with a rod that passes through two parts and is fixed on the other side. The rivets are fixed as a result of the collision of the head with the cog, after which the rod expands as a result of removal from the cog, which leads to the creation of a reliable connection between the parts. Extraction rivets are widely used in the automotive and aviation industries, as well as in construction and mechanical engineering.

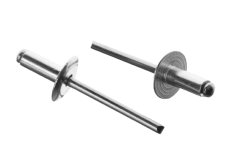

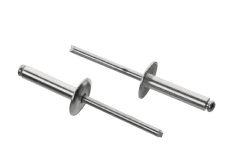

Threaded rivets

Threaded rivets are a type of rivets that are used to connect parts, in particular metal parts. They consist of two parts: a head and a threaded rod, which is inserted into the corresponding hole in the part. After the threaded rod is of the appropriate length inside the part, with the help of a special tool it is tightened on the head, which leads to the expansion of the lower part of the rod and the creation of a reliable connection.

Hammer rivets

Hammer rivets are fasteners that are used to connect two or more layers of material. They consist of two parts - the head and the rod. A rod is passed through a hole in the material and then driven with a hammer or other tool to secure the material. The rivet head serves to hold the rivet in the material, preventing it from falling out or coming to the surface. Hammer rivets are widely used in the construction, mechanical, automotive and aviation industries, as well as in the repair and manufacture of various products made of metal, wood and other materials.

Types of rivets

There are several types of rivets, each of which has its own characteristics and applications.

Reinforced rivets

Reinforced rivets are rivets that have additional grooves or faces on the surface that help improve their durability and strength. These rivets are usually made of high-strength materials such as aluminum alloys or high-carbon steels. Reinforced rivets are used in high-stress areas where ordinary rivets may not hold up. For example, they are widely used in the aviation and space industries, as well as in the automotive and shipbuilding industries.

Exhaust rivets

Pull rivets (also known as flush rivets) are a type of rivet used to join two parts, usually metal, between which there is no access from either side. They consist of two parts: a head and a cog with a rod that passes through two parts and is fixed on the other side.

Cassette rivets

Cassette rivets are special rivets used for mechanical connection of parts that have pins. They consist of a cassette containing several rivets and a mechanism for their installation.

Cassette rivets are usually used to connect parts in mechanical engineering, electrical engineering, as well as in other industries. They can be made of different materials, such as aluminum alloys, steel or stainless steel, depending on the operating conditions and requirements for strength and durability. Cassette rivets allow you to quickly and efficiently connect parts with minimal time and labor costs.

Nut rivets

Nut rivets - are rivets with a nut used to connect parts of different thicknesses. They consist of a cog, rod and nut. The screw connects the parts, and the nut helps to secure the rivet so that it does not fall out. Nut rivets are used in situations where ordinary rivets cannot be used due to the difference in the thickness of the parts, as well as in cases where it is necessary to provide additional strength and stability of the connection.

Rivets: purpose and materials of manufacture

Rivets are connection elements used to connect two or more parts. They have several advantages over other joining methods, such as welding or gluing, as they do not require special tools or equipment and do not require special skills.

Rivets are made of various materials, such as:

- Aluminum alloys: Used for rivets used in the aerospace and automotive industries, as well as in construction.

- Stainless steel: used for rivets used in the food, pharmaceutical and chemical industries, as well as for connect parts in electronics and instrument engineering.

- Black Steel: Used for rivets used in construction, engineering and other heavy duty industrial applications.

- Copper: Used for rivets used in electrical and electronics.

- Titanium: Used for rivets used in the aerospace, medical, and other demanding applications.

Advantages and disadvantages

Rivets are parts used to connect two or more materials. Here are some advantages and disadvantages of using rivets:

Advantages:

- Strength: Rivets provide strong connections because they create constant pressure between materials.

- Reliability: Rivets do not loosen over time and do not require constant support.

- Low cost: Rivets are cheap to manufacture and install, making them popular in many industries.

Despite a number of significant advantages, this fastening product has a list of disadvantages:

- Limited strength

- Impossibility of removing the rivet without damage

- Requires a special tool for installation

- Impossibility of application in thick materials

- Poor aesthetics compared to other types of connections.

Diameter and length

The diameter and length of the rivets may vary depending on the specific use and need. The diameter of rivets can be from several millimeters to several centimeters, and the length - from several millimeters to several tens of centimeters. For example, very small rivets with a diameter of 0.3 to 3 mm and a length of 1 to 20 mm are used to connect parts in electronics, while rivets with a diameter of 10 to 30 mm and a length of 10 to 30 mm are used to connect large metal structures from 50 to 150 mm.

Selection of rivet sizes

How to calculate the required size?

To calculate the required size of the rivet, you need to determine the diameter of the hole in the parts that need to be connected. The diameter of the rivet should be several millimeters larger than the diameter of the hole. You also need to take into account the thickness of the parts to be joined and choose a rivet with the appropriate length.

The following formula can be used to calculate the required rivet length:

L = (2 x t) + (d x 1.5)

where L is the required length of the rivet, t is the thickness of the material to be fastened, d is the diameter of the hole in which the rivet will be installed.

The formula is only suitable for pull and hammer rivets, as threaded rivets require selection from the catalog.

What tool will be used to set rivets securely?

For reliable installation of rivets, a special tool called a riveter must be used. A riveter is a manual or electric tool used to install rivets in metal, plastic, and other materials.

FAQ

What are exhaust rivets?

- Rivets with an imprint

- Rivets with an expanding bottom

- Rivets with a connector

- Ring rivets

- Rivets with a carved rod

What are threaded rivets?

- Classic threaded rivets

- Collapsible threaded rivets

- Round threaded rivets

- Internally carved rivets

- Carved rivets with a head.

How to determine the size of rivets?

To calculate the required size of the rivet, you need to determine the diameter of the hole in the parts that need to be connected. The diameter of the rivet should be several millimeters larger than the diameter of the hole. You also need to take into account the thickness of the parts to be joined and choose a rivet with the appropriate length.

How to choose the right rivets?

To choose the right rivets, you need to consider the following factors:

- Size: Choose rivets that are the right size for the hole in the material you are going to join.

- Material: Use rivets in a material that matches the material you are going to join.

- Head Shape: Choose the rivet head shape that suits your job. For example, a flat rivet head is suitable for connecting thin sheets, and an expanded head - for more rigid materials.

What are the sizes of rivets?

Depending on the application, rivets can have different sizes, but the most common rivet diameters are between 2 and 6 mm.

Rivets – Technical Information:

Rivets (70)

Rivets (70)