Reliable fastening: types of chemical anchors for construction

The correct choice of fasteners is already 90% of the success and reliability of your project. To create reliability in the further operation of the structure, a fairly wide range of various fastenings is used. Anchors and dowels are the most widely used in repair and construction work.

What is a chemical anchor? Features of application

This is a fastening element that is able to fix the metal embedded part as reliably as possible. The peculiarity of using chemical anchors is that an adhesive composition is injected into a hole in concrete, aerated concrete, brickwork or any other material, which after polymerization ensures exceptional reliability of the resulting connection.

Advantages of chemical anchor

A chemical anchor is the most successful and modern solution to structural reliability issues. It differs from ordinary anchors by a number of significant advantages:

1. This type of fastening has become quite widely used due to the fact that it creates particularly strong connections even in foundations, such as aerated concrete, foam blocks, as well as some types of hollow bricks;

2. The strength of the connection when using these anchors is many times higher than when using an ordinary metal anchor;

3. They are particularly resistant to aggressive environmental conditions. In some cases, they can be used even in wet holes.

4. Seal the mounting hole.

5. Unlike metal anchors, when using a chemical anchor, the inner wall of the hole is not subjected to mechanical stress.

6. The service life is more than 50 years.

Fields of application of chemical anchors

- Fastening, as well as complete replacement of fittings during the construction of responsible structures (bridges, stairs, ceilings);

- Expansion of the foundation, connection of walls, increase of columns and stairs;

- Fixation of steel elements;

- Construction;

- Installation of auxiliary equipment;

- Installation of equipment;

- Fastening structures under water;

- Construction of high-rise buildings;

- Formation of the foundation of quickly erected buildings even under difficult conditions;

- binding of heavy assembly beams;

- creation of reinforcement releases during monolithic construction.

Types of chemical anchors

Despite the large list of fields of application, chemical anchors are mainly of two types: in tubes and cartridges; in separate ampoules for a certain depth and diameter of the hole.

How to choose the right chemical anchor?

The main thing to pay attention to is the area of application of the adhesive mass; the nature of the load; base material and its structure; what type of tool was used to prepare the hole for installing the anchor (diamond or conventional drill); installation temperature and humidity. Based on this, choose the chemical composition of the anchor.

.jpg)

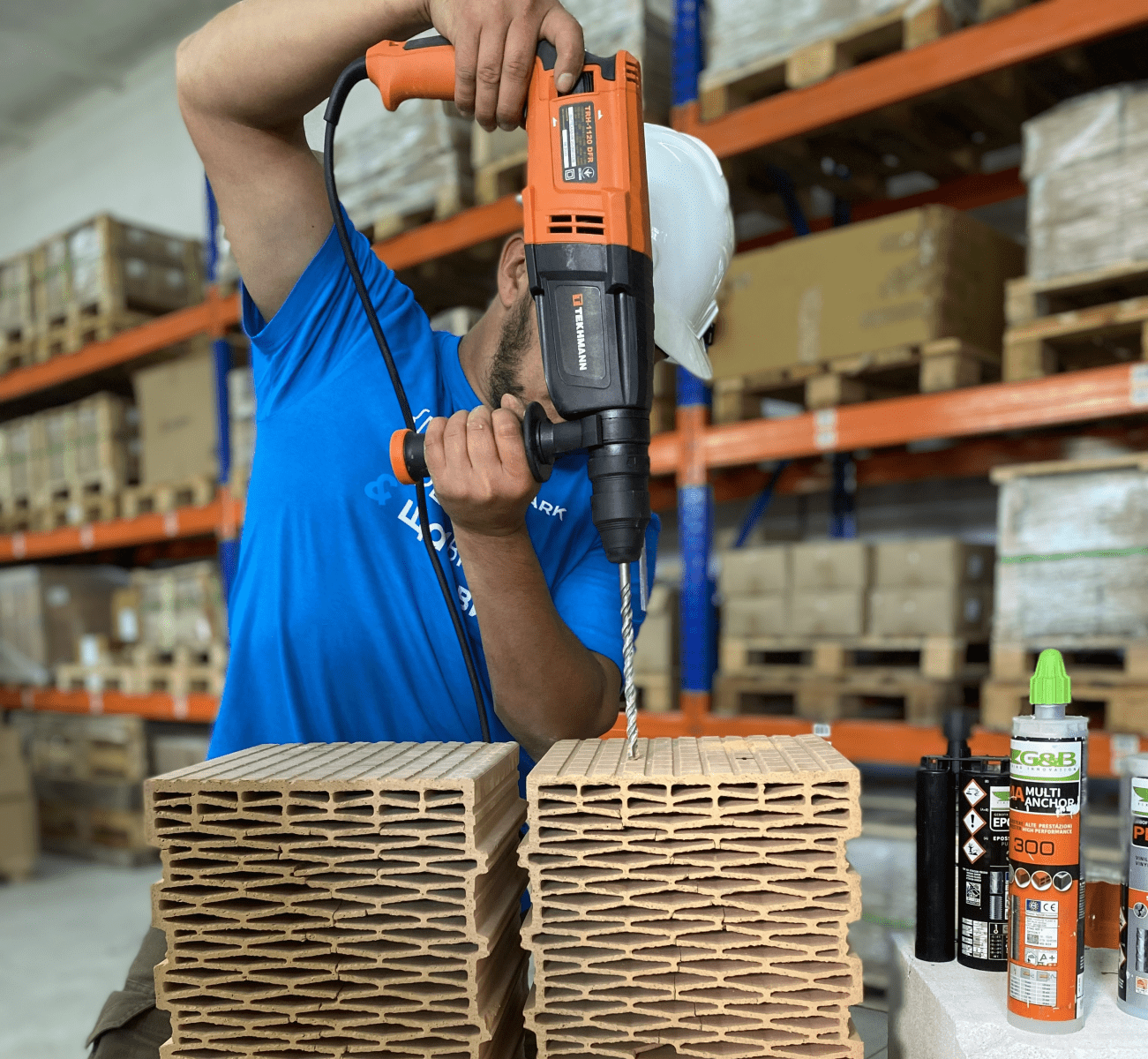

Stages of installation of a chemical anchor

When installing an ampoule chemical anchor, a hole is first drilled, which is thoroughly cleaned, and only then is the installation performed. The mixing of the components of the composition and its polymerization occurs due to the fact that a pin is inserted into the hole, which destroys the capsule and its internal partition. Its advantage is that it is not necessary to control the filling of the hole.

The technology of using chemical anchors in cartridges is a more universal solution and is suitable for installation conditions on objects with different sizes of holes, installation conditions and base materials. To use them, you need a special gun that squeezes the chemical anchor into the hole. This type of anchor is often used in large-scale works, because if a closed anchor has a shelf life of about 6 months, then an open one has a shelf life of about 14 days.

Calculation of costs of chemical anchors

To calculate the volume of material per hole, you can use the formula:

V анк= п х h(D^2 -d^2)/4

n is the number of Pi

h - hole depth

D - the diameter of the hole drilled

d - the diameter of the pin that will be used.

When choosing an anchor special attention should be paid to the fact that the rate of its hardening directly depends on its chemical properties, as well as the ambient temperature.

You can buy G&B and Fischer chemical anchors in our online store.

Anchors (13)

Anchors (13)