|

Steel - is an alloy of iron with carbon (up to 2.14%) and, in some cases, with other alloying elements. It differs from cast iron in its lower carbon content, which provides the main advantage — a combination of high strength with good machinability and plasticity. That is, it is a material that can be easily shaped, cut, welded and adjusted to any needs without losing its durability. That is why it is so universal. In the broadest sense, steel is divided into two broad categories: carbon and alloy. Dbut they are divided into narrower subspecies depending on the carbon content, alloying elements and purpose. With the ability to control the chemical composition and processing, the steel can be adapted to a variety of requirements, from super-tough armored protection to ultra-thin surgical needles. This opens up endless possibilities for engineers and developers. Next, we will take a detailed look at the classification of steels in order to better understand what types exist and what each of them is for. |

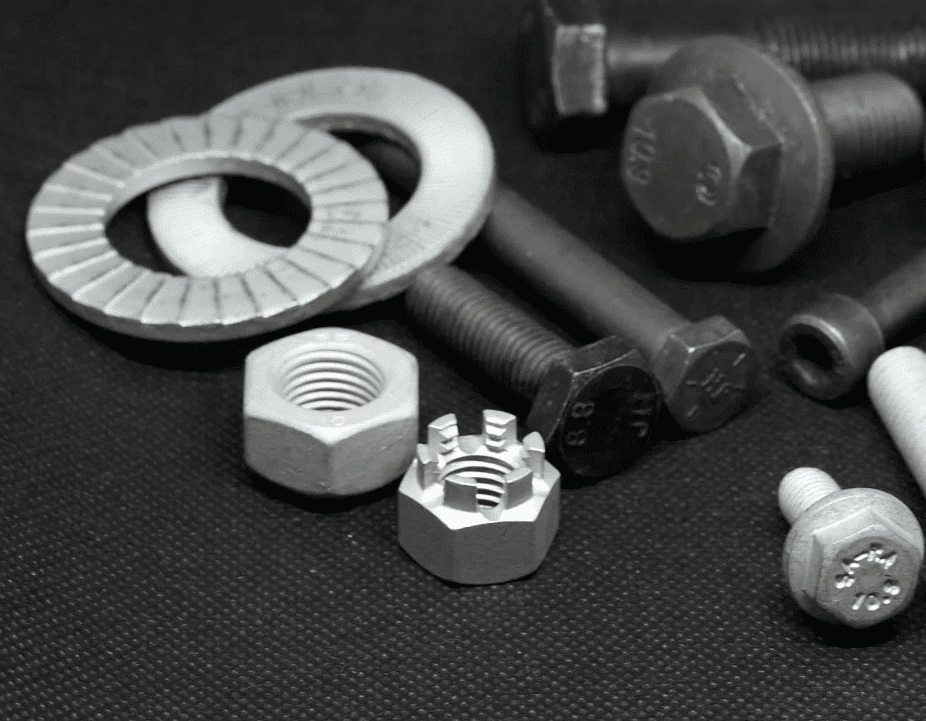

Fig.1 Types of steel |

Classification of steels

Classification of steel is the first step towards its correct selection. The steel you choose will depend on its strength, wear resistance, machinability, and even price. In industry and construction, there is no universal steel - for each task, the optimal type of steel is selected.

Classification by chemical composition

Carbon steel

It is the simplest type of steel, which consists mainly of iron and carbon. It does not contain significant amounts of additional alloying elements. Carbon steels are divided into three categories depending on the carbon content: low carbon (up to 0.25%), medium carbon (0.25–0.6%) and high carbon (over 0.6%). The more carbon, the harder and more brittle the steel. Carbon steels are inexpensive, weld well, but have low wear resistance and corrosion resistance.

Alloy steel

This is steel, which includes additional chemical elements that significantly affect its properties. Chromium, nickel, molybdenum, vanadium or manganese, etc. are often added. They make the material more resistant to corrosion, strong, heat-resistant or wear-resistant. According to the number of alloying elements, alloy steel is divided into: low alloy (up to 2.5% alloying elements); medium alloy (2,5–10%); high-alloyed (over 10%).

Classification by purpose

Structural steel

This type of steel is intended for the creation of load-bearing frames, supporting elements, beams, machine chassis, etc. It has good weldability, stable strength and resistance to mechanical loads. It is marked as St3, 10, 20, 45, etc. There is also a division of structural steels into groups:

Group A — steels with guaranteed mechanical properties, but without strict regulation of the chemical composition. They are easy to process, but the composition may vary from batch to batch.

Group B — steels with a precisely defined chemical composition, and the properties are achieved through heat treatment. They are used where accuracy is important.

Group C — a combination of the two previous ones: chemical composition and mechanical properties are regulated. They are most often used in responsible structures.

Tool steel

These are steel alloys from which cutting, stamping, measuring and other types of tools are made. They have high hardness, wear resistance and retain these properties even when heated. There are:

Special purpose

These are steels that are used in special conditions — elevated temperature, aggressive chemical environments, high pressure. These include: Ball bearing steels — high wear resistance and durability due to the chromium content. Heat-resistant steels — work at temperatures above 600 °C without loss of mechanical properties. Acid-resistant and corrosion-resistant steels — for chemical equipment, pipelines, tanks.

Each of these categories is created for clearly defined operating conditions, so a competent choice of steel is the key to reliable and long-lasting operation of any mechanism or structure.

The main properties of steels

The choice of steel is always based on its properties. It is the physical, mechanical and chemical characteristics that determine the scope of application of a specific type of steel. In this section, we will consider the key parameters by which the quality and efficiency of the steel alloy are evaluated.

Mechanical properties

- Strength

This is the ability of steel to resist external mechanical forces - pressure, stretching, bending or twisting. The higher the strength, the greater the load the structure can withstand without breaking. For example, type 45 structural steels have high strength, which allows them to be used in critical mechanical components.

- Hardness

Means the ability of the material to resist the penetration of another body. This is an important characteristic for tool steels. It is measured according to Brinell, Rockwell or Vickers scales. High-speed steels have a hardness of up to 65 HRC and even more, which allows them to maintain their cutting ability at high temperatures.

- Plasticity

Determines the ability of steel to deform without the formation of cracks or breaks. Carbon steels with a low carbon content (type St3) have high ductility and are well welded. Ductility is important for parts subject to repeated bending or impact.

- Viscosity

This is the ability of a material to absorb mechanical energy during an impact without collapsing. Tough steels better withstand dynamic loads that occur, for example, in vehicles or machine mechanisms.

Physical properties

Thermal conductivity

One of the key characteristics for steels used in heat exchangers, engines, pipelines. For example, in heat-resistant steels, thermal conductivity must be stable even at high temperatures.

Heat resistance

This is the ability of steel to maintain its mechanical characteristics when heated. For high-speed cutting tools, it is important that the steel does not lose its hardness even at temperatures up to 650 °C.

Conductivity

Although steel is not a good conductor, this property is important for certain engineering tasks. Electrical conductivity decreases with the addition of alloying elements.

The magnetic properties of steel depend on its composition and processing. Read more about magnetic properties in the article: What is the difference between magnetic and non-magnetic stainless steel?

Chemical properties

Chemical and corrosion resistance

The presence of chromium in the composition of steel ensures the formation of a passive protective film on the surface, which prevents corrosion. AISI 304 or 316 stainless steels are widely used in the food, medical and chemical industries precisely because of this property.

Influence of alloying elements

Chrome - increases wear resistance, hardness, corrosion resistance. At a content of more than 12%, it creates a passivating layer that prevents oxidation. Nickel - improves plasticity, strength, corrosion resistance. Steels with nickel are used in refrigeration equipment, chemical industry. Tungsten - retains hardness at high temperatures. An important component of high-speed and heat-resistant steels. Molybdenum - helps increase heat resistance and strength during prolonged heating. Also improves weldability and corrosion resistance. Vanadium - increases impact toughness and fine-grained structure, which positively affects the durability of steel.

Thus, steel properties are not just a list of technical characteristics. This is a set of indicators that allows you to adapt the material to any technological or operational conditions, ensuring safe, reliable and durable work in all areas of human activity.

Table of chemical composition of steels

|

Designation |

Deoxidation method |

Carbon for products with nominal thickness in millimetres |

Silicon |

Manganese |

Phosphorus |

Sulphur |

Nitrogen |

Copper |

Others |

|||

|

In accordance with EN 10027-1 and CR 10260 |

In accordance with EN 10027-2 |

>16 |

>16 40 |

> 40 |

%, not more than |

|||||||

|

S235JR S235JO S235J2 |

1.0038 1.0114 1.0117 |

FN FN FF |

0,17 0,17 0,17 |

0,17 0,17 0,17 |

0,20 0,17 0,17 |

- - - |

1,40 1,40 1,40 |

0,035 0,030 0,025 |

0,035 0.030 0,025 |

0,012 0,012 - |

0,55 0,55 0,55 |

- - - |

|

S275JR S275JO S275J2 |

1.0044 1.0143 1.0145 |

FN FN FF |

0,21 0,18 0,18 |

0,21 0,18 0,18 |

0,22 0,18 0, 18 |

- - - |

1,50 1,50 1,50 |

0,035 0,030 0,025 |

.. 0,035 0,030 0,025 |

0,012 0,012 - |

0,55 0,55 0,55 |

- - - |

|

S355JR |

1.0045 |

FN |

0,24 |

0,24 |

0,24 |

0,55 |

1,60 |

0,035 |

0,035 |

0,012 0,012 - - |

0,55 |

- |

|

S355JO |

1.0553 |

FN |

0,20 |

0,20> |

0,22 |

0,55 |

1,60 |

0,030 |

0,030 |

0,55 |

- |

|

|

S355J2 S355K2 |

1.0577 1.0596 |

FF FF |

0,20 0,20 |

0,20> 0,20> |

0,22 0,22 |

0,55 0,55 |

1,60 1,60 |

0,025 0,025 |

0,025 0,025 |

0,55 0,55 |

- - |

|

|

S450J0 |

1.0590 |

FF |

0,20 |

0,20> |

0,22 |

0,55 |

1,70 |

0,030 |

0,030 |

0,025 |

0,55 |

|

*Exceptions to the table are possible regarding the chemical composition of steel depending on the type of product, its thickness or special treatment. For example, it is allowed to increase the content of sulfur or phosphorus for long products or to change the content of carbon and nitrogen by agreement, if this is confirmed by the relevant documentation. Detailed technical conditions, including all exceptions and additional requirements, are given in "NATIONAL STANDARD OF UKRAINE. HOT ROLLED PRODUCTS OF STRUCTURAL STEEL. Part 2. Technical conditions of supply of non-alloy structural steels (EN 10025-2:2004, IDT) DSTU EN 10025-2:2007"

Marking of steels usually includes numbers and letters indicating the composition of the material, its characteristics and purpose. This allows you to quickly determine the type of steel, its properties and possible areas of use. Read in more detail in the article: Stainless steel grades

Steel quality control

Quality control of steel products is an important part of production, which guarantees compliance of products with technical requirements and standards. Depending on the conditions of supply, the control can be specific or non-specific. In non-specific control, basic tests are carried out, and the results are issued as a certificate of conformity. In the specific case, the list of checks is wider, and everything is recorded in detailed technical documentation. The type of control and the form of reporting are determined in accordance with the requirements of the European standard EN 10025-1. The frequency of tests is established depending on the quality group of steel and the method of its supply - by batches or by melts. Test units are formed from materials of the same brand, thickness and condition of delivery. Tests for tensile strength, chemical composition and impact toughness are mandatory during the inspection. Individual additional tests may be agreed at the time of ordering. In general, the main attention is paid to quality groups, because they determine the ability of steel to withstand shock loads, especially at low temperatures. The quality groups are designated as JR, J0, J2 and K2. The "higher" the group, the better the impact resistance of the steel. For example, group JR steel has a basic impact toughness, while J2 and K2 provide much better resistance to brittle fracture. This is important in conditions of increased load or in cold climates, where the material can quickly fail without proper quality. As for test methods, chemical analysis is carried out in accordance with the requirements of the EN 10025-1 standard. Mechanical tests are also carried out according to the same standard. Ultrasonic testing is performed in accordance with EN 10025-1. If necessary, repeated tests are also carried out in accordance with the provisions of EN 10025-1. Thus, the control system allows you to confidently assess the quality of steel and ensure its reliability in any conditions of use.

In general, the advantages of steel are its high strength and durability: due to its high tensile and compressive strength, steel can withstand high loads without breaking, making it an ideal material for use in industrial structures. In addition, its production is relatively inexpensive, and the service life is decades, which makes steel an economically advantageous material. Due to alloying elements such as chromium, nickel or molybdenum, or heat treatment, it is possible to change the properties of steel, making it heat-resistant, stainless, wear-resistant or extremely hard. This allows you to get many different options of steel for different purposes. In general, metalworking steels are often made from carbon and alloyed alloys, where the content of carbon and alloying elements determines the properties of the steel and its machinability, mechanical properties and wear resistance. One of the most common types is steel grades 45, 50, 65 and chrome-nickel steels dfor the production of high-quality hardware.

Dinmark offers fastening products made from various types of steel, allowing customers to choose the optimal solution for any application — from household to industrial use. The quality, reliability, and variety of products make Dinmark a trusted partner in fastening solutions.