The original SCHNORR® safety washers were developed as a reliable and economical device for locking bolts against self-twisting based on the basic principle of a disc spring washer. This ingenious shape combines the advantages of friction and mechanical locking.

The original SCHNORR® safety washers were developed as a reliable and economical device for locking bolts against self-twisting based on the basic principle of a disc spring washer. This ingenious shape combines the advantages of friction and mechanical locking.

The original SCHNORR® safety washers are now used worldwide wherever reliable fastening connections are required to counteract vibrations.

The areas of application are wide-ranging: from the automotive industry to mechanical engineering, plant engineering and factory construction. SCHNORR® safety washers are used, for example, in lawn mowers, textile machines, machine tools and many other areas.

Properties and applications in modern production

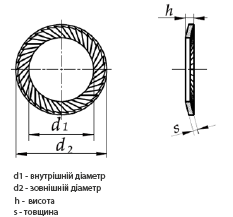

| The original SCHNORR® safety washers are shaped like a spring disk with a trapezoidal cross-section and teeth on both sides. The outer diameter corresponds to the diameter of the head of a flat (semicircular, hexagonal) or countersunk screw. SCHNORR® safety washers are available in two versions:

|

|

Materials and construction of Snohomish washers

Not only do Snohomish washers impress with their technical efficiency, but they are also made of high-quality materials that provide unrivaled reliability and durability. It is important to note what materials they are made of and how this affects their properties.

The main material used for the manufacture of Schnorr washers is high-strength steel. This material is known for its strength and resistance to mechanical stress, which makes it ideal for fasteners that are subject to high loads and vibrations.

The design of Schnorr washers also includes special ribs that help keep them in place during heavy use. These ribs are integrated with vibration loads in mind, providing additional protection and stability in the field.

Thanks to the use of high quality materials and a carefully engineered design, Schnorr washers are guaranteed to be durable and reliable in a variety of operating conditions. This makes them an unbeatable choice for projects where the quality of fastening and protection of structures against vibrations and loads are important.

Technical advantages and outstanding resistance in the Junker test

What makes Schneider washers stand out from other fasteners? The answer is their outstanding technical properties, especially their high level of resistance, which has been proven in tests such as the Junker test. But these are not all their advantages

1. High resistance to vibrations: The robust tooth locking ensures high resistance to vibrations, reducing the risk of loosening.

2. Uniform transmission of forces and distribution of moments: Concentric force transmission and uniform axial load eliminate the occurrence of bending moments and deformation of the bolt body.

3. Prevent friction and damage during tightening: The tooth design prevents friction and damage to components during tightening.

4. High level of safety against loss of tension and loosening: Provides an extremely high level of safety against loss of tension and loosening.

5. Wide range of materials and coatings: A variety of materials and different types of finishes offer a wide range of choices.

6. Closed ring shape for high tension levels: The closed ring shape ensures a high degree of tension, avoiding the effect of washer breakage.

7. Development and design based on bolt geometry, tightening torque and structural circumstances: The development and design process of washers is based on the bolt geometry, tightening torque and structural circumstances.

The Junker test is a standardized method for determining the resistance of fasteners to vibration loads. This test involves systematic testing of fasteners under real-world conditions, which allows us to evaluate their effectiveness in conditions of intense vibration.

The Schnorr washers impressed in the Junker test, where they demonstrated outstanding resistance to vibration loads. The high level of performance in this test demonstrates their ability to effectively retain the load under vibration, ensuring a high level of safety and reliability in extreme operating conditions.

The results of the Junker test not only indicate the high technical level of Schneider washers, but also confirm their practical applicability. Thanks to these properties, they are becoming an integral part of structures where vibration resistance and safety under high mechanical loads are important.

Applications in various industries

Schneider washers are not only technically superior, but also have a wide range of applications, especially in important industries such as mechanical engineering and construction.

In the mechanical engineering industry, Schneider washers have become an important element of structures where a high level of reliability and resistance to mechanical and vibration effects are crucial. They are used in various components and machine parts, ensuring their efficient operation under high loads and vibrations.

In the construction industry, Schneider washers are used to ensure that structures are resistant to vibration loads. Building elements equipped with these washers demonstrate a high level of efficiency and safety, which is critical in large construction projects.

The use of Schnorr washers in mechanical engineering and construction is the best proof of their versatility and the high degree of trust they have gained in the professional industries in Europe. These fasteners are not only distinguished by their advanced technical characteristics, but also by their wide range of features to ensure reliability and safety in a variety of applications.

Managing maximum loads with minimum fasteners

SCHNORR® washers withstand many dynamic processes in a resourceful, safe and efficient manner - often under extreme load and pressure.

In order to develop and produce perfectly matched solutions for various applications, SCHNORR offers a large range of spring washers, together with many special sizes to meet customer needs, which can be viewed on our Dinmark website.

SCHNORR® washers are distinguished:

- The linear, progressive nature of the load bending curve.

- Long and consistent service life under dynamic loading.

- The use of high-quality materials.

- Exact adherence to the declared strength and dimensions specified in the drawings.

But what makes them even better? You can purchase these high-quality washers directly from our DINMARK website. Our online store offers not only a wide range of fasteners, but also advice from our experts so that you can make the best choice for your project. Choose high quality and reliability from DINMARK.

Cart

Cart  Wish list

Wish list

Comparison.

Comparison.  Washers, rings (15)

Washers, rings (15)