When we work with the mount — bolts, nuts, washers or anchors— accuracy plays a key role. It seems that a difference of a few tenths of a millimeter does not matter, but in reality even a micro error can be costly. Imagine the situation: you selected a bolt, drilled a hole, installed it in a structure, and under load it begins to wobble or even collapse. Why does this happen? In most cases, the reason is banal — incorrect measurements. It is here that a tool that allows you to work with maximum accuracy comes to the fore — caliper. It is an indispensable assistant both for engineers and craftsmen, as well as for ordinary users facing technical tasks at home. Without it, it's like having no hands in assembly, metalworking or even simple repairs. A caliper is a high-precision measuring tool that is indispensable in technical fields for determining the dimensions of objects with great accuracy. Thanks to it, it is possible to measure external and internal diameters, as well as the depth of holes, which makes it necessary when working with fasteners, machine parts, mechanisms, and even in such precision industries as mechanical engineering and metalworking.

The caliper allows you to determine not only the outer and inner diameters of the parts, but also the depth of the holes. Thanks to this, we get full control over the process of selecting a fastener: whether it is a bolt for a nut or an anchor in concrete. It gives accuracy to the hundredth of a millimeter, which makes it a must in professional work.

What is a caliper?

A caliper is a high-precision measuring tool that is used to determine the external and internal dimensions of parts, as well as to measure the depth of holes. Its uniqueness lies in its multifunctionality: one tool can perform several types of measurements at once. Historically, the caliper appeared as early as the 19th century and quickly became the standard of precision in mechanics. At first it was a simple mechanical device with a vernier scale, later dial and digital versions appeared. Regardless of the form, the main purpose of the tool has not changed - to provide the most accurate measurement. In the modern world, calipers are used in mechanical engineering, construction, repair of machinery, in furniture production, and even in everyday life. It helps to check whether the fastener meets the required parameters and avoid situations where a small error leads to big problems.

Basic types of calipers and their differences

Today there are three main types of calipers:

- Mechanical (non-oral) — a classic instrument that does not require batteries. The reading of readings takes place thanks to a special scale — a vernier. This is the most reliable and durable option that works even in difficult production conditions.

- Digital — modern and comfortable. It has an electronic display that instantly shows the result. This significantly saves time and reduces the possibility of reading errors. However, such a tool depends on batteries and can be sensitive to moisture or magnetic fields.

- Dial — an intermediate option between mechanical and digital. It has an arrow indicator that simplifies the operation. However, today it is used less often, because it is inferior to digital models in terms of speed and mechanical in terms of reliability.

Vernier or digital calipers are most often used to work with fasteners. The first is suitable for the most accurate measurements, the second - for speed and convenience. The debate about which caliper is better - digital or mechanical - continues today. Each option has its own strengths and certain disadvantages. Mechanical or vernier calipers are famous for their reliability. It does not depend on batteries, is able to work even in difficult conditions and provides high accuracy to hundredths of a millimeter. This is a tool that will last for decades if handled properly. Its main feature is that the readings must be read manually from the vernier scale. It may seem difficult for beginners, but after a few practices the principle becomes clear. The digital caliper is more modern and convenient to work with. Its advantage is that the result immediately appears on the display. This saves time and reduces the chance of reading errors. This option is especially useful during serial measurements, for example in production. However, the digital tool depends on the battery, which can die at the most crucial moment. There is also a risk of error when the battery is low or exposed to external factors such as humidity or magnetic fields.

Therefore, the choice depends on the tasks. If you need absolute reliability, you should use a mechanical device. If the main thing is speed and comfort, then digital will be the best solution. Experienced masters often have both options and use them in different situations.

Structure and basic elements of a caliper

In order to use a caliper correctly and take accurate measurements, you must first understand its structure. At first glance, this tool looks simple, but each of its elements performs a clearly defined function. It is thanks to the combination of these parts that the caliper became a universal device that is used both in mechanical engineering and in construction or even in everyday life.

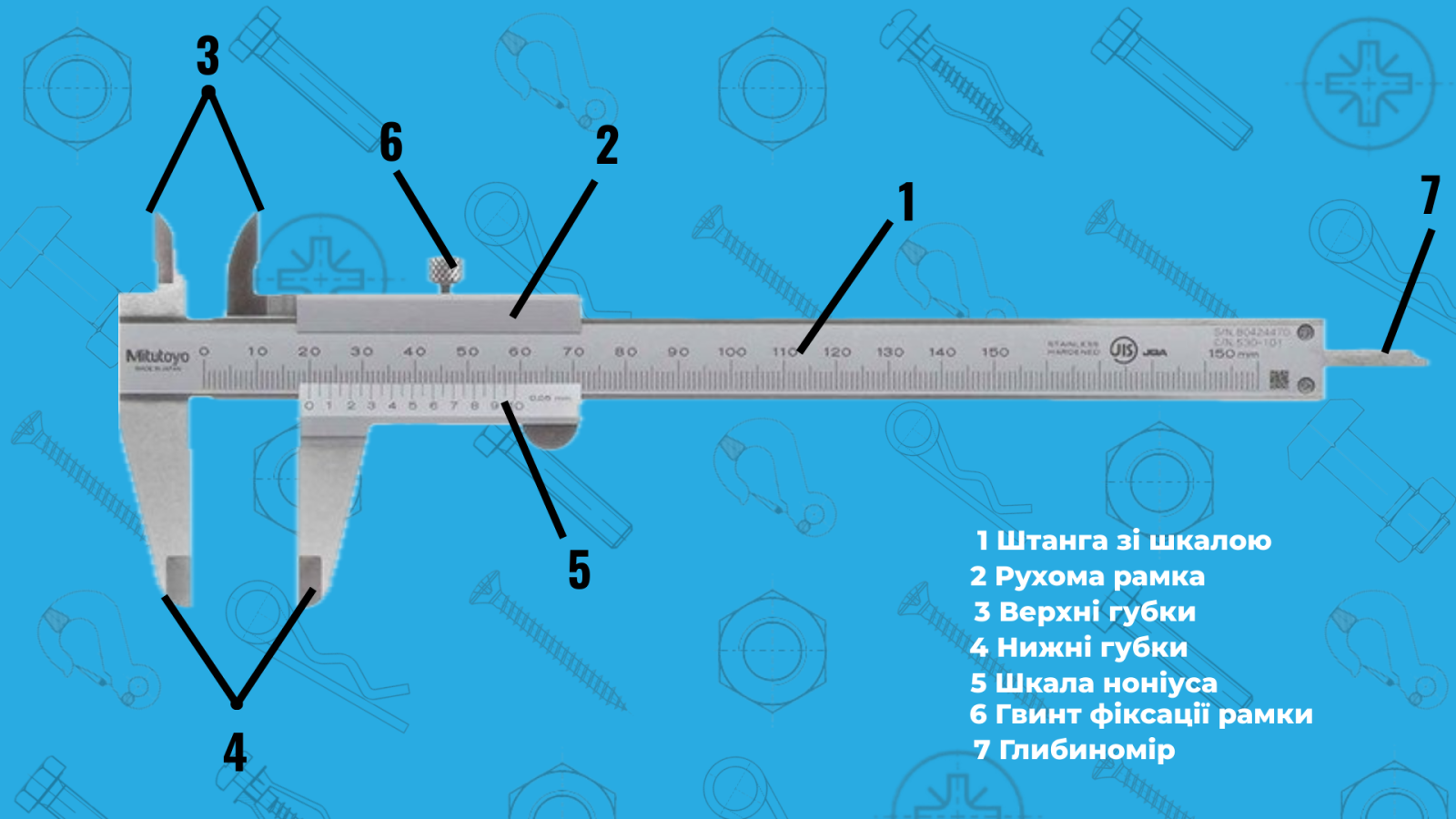

The main parts of the caliper (see Fig. 1) are:

- bar with scale (1) it is a long metal profile marked with millimeter divisions. It is the basis along which the frame moves. It is thanks to this scale that it is possible to determine the value of measurements in combination with other elements. The quality of applying divisions directly affects the accuracy of reading the results, therefore, in professional tools, they are performed by laser engraving.

- moving frame (2) ensures smooth sliding along the rod and allows you to set the exact position of the measuring jaws. It is equipped with a mechanism that does not allow backlash, because even a small displacement during operation can lead to an error. For convenience, a vernier or digital sensor is built into the frame, depending on the type of caliper.

- lower lips (4) located at the bottom of the instrument. They consist of two elements: one sponge is fixed, the other moves with the frame. Their main purpose is external measurements. For example, the diameter of the bolt, the thickness of the washer or the width of the metal profile are determined precisely with the help of the lower jaws.

- upper lips (3) located above the lower ones and have a smaller size. They also consist of a fixed and a moving part, but are already used for internal measurements. These can be diameters of holes in nuts, pipes, bearings or any other parts with internal cavities. Thanks to the narrow ends of the sponges, they easily enter the hole and allow you to get an accurate result.

- vernier scale (5) one of the key elements of a mechanical caliper. It is an additional scale applied to the frame, which allows you to obtain values with an accuracy of tenths or even hundredths of a millimeter. The principle of its operation is based on the difference in the pitch of the divisions between the main scale and the vernier. It is thanks to this that it becomes possible to determine values that significantly exceed the accuracy of a conventional ruler.

- depth gauge (7) this is another important element that is often underestimated. This is a thin retractable rod located at the opposite end of the rod. It is used to determine the depth of holes, grooves or seats for fasteners. This feature is especially useful when installing anchors, dowels, or countersunk screws when you need to make sure the hole is deep enough.

- locking screw (6) completes the tool design. Its main task is to block the moving frame after the jaws have tightly covered the part. This allows you to avoid accidental displacement and maintain the accuracy of the measurement until the moment of reading the indicators. This is critically important for work with fasteners, because even the smallest movement can cause an error of several tenths of a millimeter.

Fig. 1 Structure of caliper

In a complex, all these elements make a caliper indispensable. One tool allows you to measure external and internal dimensions, determine depth, and perform accurate measurements with minimal error. This saves time, simplifies work and guarantees the quality of connections in any area where hardware and fasteners are used.This structure makes the tool universal: with one device, several critical fastening parameters can be obtained at once.

How to use a caliper properly?

It is not difficult to master a caliper, the main thing is to understand what each part of it is for. The most common way to use the tool is external measurements. For example, to determine the diameter bolt or thickness washers, use the lower jaws. The part is carefully placed between them, the jaws are slightly compressed until the moment of contact, after which the result is read from the main and vernier scale or from the display in the digital model. The second method of use is internal measurements. For this, upper jaws are used, which are inserted into the part, for example, into a nut or pipe. Next, the sponges are pushed apart until they come into contact with the walls. This technique allows you to accurately determine the inner diameter and match the bolt to the nut or check the hole for the anchor. The third option for working with a caliper is depth measurement. A depth gauge is used for this. It is pushed to the bottom of the hole, while the end of the rod rests tightly on the surface of the part. This method is indispensable in cases where it is necessary to check the depth of the recess for dowels or screws with a countersunk head. The main rule of using a caliper is to work without haste, smoothly and carefully. This is not a tool for quick measurements "by eye", but a device for maximum accuracy.

Frequently asked questions and answers:

What is the permissible error in measuring with a caliper?

The standard accuracy of most models is from 0.02 to 0.05 mm. For fastener work, even tenths of a millimeter can make a difference, so it's important to check exactly how much tolerance your tool has. Models with an accuracy of 0.02 mm are recommended for professional use.

How to read the vernier scale correctly?

First, the whole part of the measurement on the main scale is determined - this is the division that is in front of the zero of the vernier. Then you need to find the division on the vernier that coincides with the division of the main scale. It is this number that is the decimal part of the measurement. This method allows you to get the most accurate result without guesswork.

How often do you need to check the accuracy of the caliper?

It all depends on the conditions of use. If the instrument is used in production conditions, it is recommended to calibrate it at least once every six months. It is also important to store the tool carefully and avoid mechanical damage.

Typical measurement errors and tips for correct use

Having a quality tool does not guarantee correct results. Measurement errors are common, and even a small deviation can significantly affect the reliability of the connection.

Follow these guidelines to get the right results:

- Before work, check the condition of the caliper. Sponges must be clean, without burrs and damage.

- Always make sure that the part you are measuring is clean. Any particles of dust or rust can affect the readings.

- During external measurements, place the jaws parallel to the surface of the part.

- Do not apply excessive pressure to the part - this can lead to deformation and distortion of the results.

- Use a depth gauge for holes and grooves, and top jaws for internal measurements only.

- After receiving the result, fix the frame with a screw - this way you will avoid displacement of the device during reading.

- For digital models, always check the battery charge.

- Always pay attention to the specified error of the tool and take it into account in the measurements.

- Regularly check the condition of the device, clean it after use and store it in its case.

It seems that these nuances are not of great importance, but in the work with fasteners, it is the accuracy that determines the strength, tightness of the fit and durability of the entire structure. A caliper is one of those tools without which it is difficult to imagine any technical work. It allows you to determine the external and internal dimensions of parts, as well as the depth of holes, with high accuracy. It is thanks to him that we avoid critical errors that can lead to a decrease in the strength of the connection or even to the complete destruction of the structure. Whether you're using a classic mechanical vernier caliper or a modern digital version, the principle remains the same - accuracy above all else. A mechanical tool gives confidence in durability and does not depend on batteries. Digital provides speed and comfort, especially when many measurements need to be made. Each option has a right to exist, and the choice depends on specific conditions and work requirements. Errors in measurement most often occur due to inattention. Improper jaw position, too much pressure, ignoring instrument error, or using a worn tool all lead to inaccurate results. At the same time, if simple rules are followed, the caliper will always show the most correct value. Accuracy in work with fasteners is not a whim, but a real necessity. How strong, reliable and durable the structure will be depends on the correct measurement. Therefore, the caliper can be called a guarantee of a professional approach. Use it, and none bolt or screw will not let you down at the most important moment.